In the competitive landscape of manufacturing, efficiency is paramount. Process control engineering plays a critical role in achieving optimal performance. Dr. Emily Carter, a renowned expert in the field, has remarked, “Effective process control is the backbone of modern industry.” This statement echoes the significance of advanced techniques designed to enhance operational efficiency.

A myriad of strategies exist within process control engineering. These techniques revolve around automation, real-time monitoring, and predictive analytics. Each method serves a defined purpose. For instance, automation reduces human error, while real-time monitoring ensures immediate response to anomalies. However, implementing these solutions often presents challenges. Companies may struggle with outdated systems or lack the necessary expertise.

As we explore the top ten techniques in this domain, it’s essential to acknowledge that perfection is not the goal. Mistakes can lead to valuable insights. The journey toward increased efficiency through process control engineering is ongoing. Embracing both successes and setbacks can foster innovation in this vital field.

Process control engineering plays a crucial role in enhancing industrial efficiency. It involves managing and optimizing production processes. Effective process control can reduce waste, improve product quality, and lower operational costs. However, many industries still struggle with outdated techniques. There's often a reliance on manual operations, leading to inefficiencies. This gap presents opportunities for innovation and improvement.

Utilizing advanced control techniques is essential. Techniques like PID control, model predictive control, and real-time monitoring can greatly enhance performance. Yet, the adoption of these methods is not universal. Companies may hesitate due to costs, training, or complexity. This resistance can lead to stagnation. Industry professionals must rethink their approach and consider integrating new technologies. Embracing change is not easy, but it can yield significant benefits in the long run.

Regular evaluations of existing systems can highlight areas for improvement. Identifying bottlenecks or repetitive errors is vital. Investing in continuous training for staff can also promote a culture of efficiency. Engaging employees in this process fosters innovation. As industries evolve, adapting to new challenges is necessary. It can be uncomfortable, but it’s essential for sustained growth and efficiency.

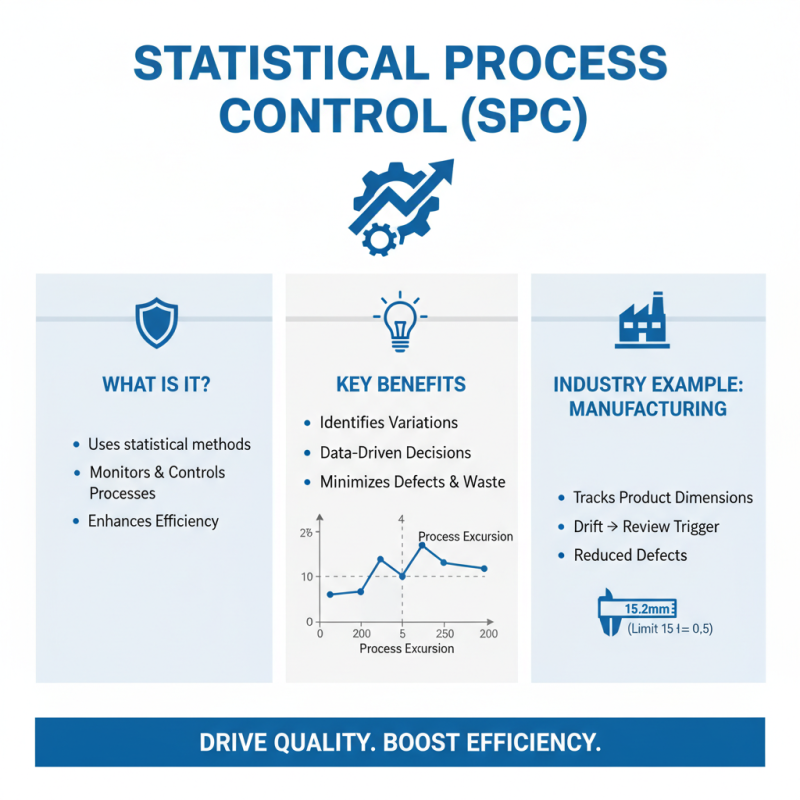

In today's competitive landscape, data-driven process control plays a vital role in optimizing efficiency. Techniques like statistical process control (SPC) allow engineers to monitor variations in processes effectively. By analyzing real-time data, teams can identify and address issues quickly, leading to enhanced production and reduced waste.

Tips: Use automation tools to gather data consistently. Automating data collection helps minimize human error. It's essential to ensure that data streams are reliable and accurate.

Another key technique is machine learning integration. By implementing algorithms, organizations can predict failures before they occur. This proactive approach saves time and resources while maintaining operational performance. However, machine learning requires quality data and expert interpretation.

Tips: Focus on data quality. Clean and relevant data will yield better model performance. Keep revisiting your data sources to confirm their reliability.

Lastly, visualization tools can enhance decision-making. Graphs and dashboards transform complex data into understandable formats. Engineers can quickly spot trends and anomalies. Yet, over-reliance on visualization may blind teams to subtle issues that require deep analysis.

| Technique | Description | Benefits | Application Areas |

|---|---|---|---|

| PID Control | Proportional-Integral-Derivative control is a control loop feedback mechanism that continuously calculates an error value. | High accuracy, stability in process control, and reduced oscillations. | Chemical processes, temperature control. |

| Model Predictive Control | An advanced control strategy that utilizes a dynamic model of the process to predict future outcomes. | Efficient handling of multivariable control problems and constraints. | Oil refining, power generation. |

| Fuzzy Logic Control | A form of control that handles uncertain or imprecise information using fuzzy set theory. | Good performance in complex processes, easy to implement. | Automotive systems, HVAC systems. |

| Data Analytics | The use of statistical and computational techniques to analyze and interpret process data. | Improved decision-making and real-time insights. | Manufacturing optimization, quality control. |

| Neural Networks | A computational model inspired by the human brain's neural networks, used for pattern recognition. | Ability to learn from data, adaptability to changes. | Predictive maintenance, process fault detection. |

| Simulation Modeling | Using models to simulate the behavior of processes over time. | Cost-effective process testing and optimization. | Chemical engineering, system design. |

| Statistical Process Control | Utilizes statistical methods to monitor and control a process. | Reduces variability, improves process quality. | Manufacturing, service industries. |

| Batch Control | Control of processes that produce products in batches rather than continuously. | Flexibility and customization in production. | Food production, pharmaceuticals. |

| SCADA Systems | Supervisory Control and Data Acquisition systems provide real-time data collection and control. | Improved monitoring and operational efficiency. | Water treatment facilities, power systems. |

| Internet of Things (IoT) | Integration of IoT devices in process control for enhanced data collection and real-time monitoring. | Increased connectivity and efficiency. | Smart factories, logistics management. |

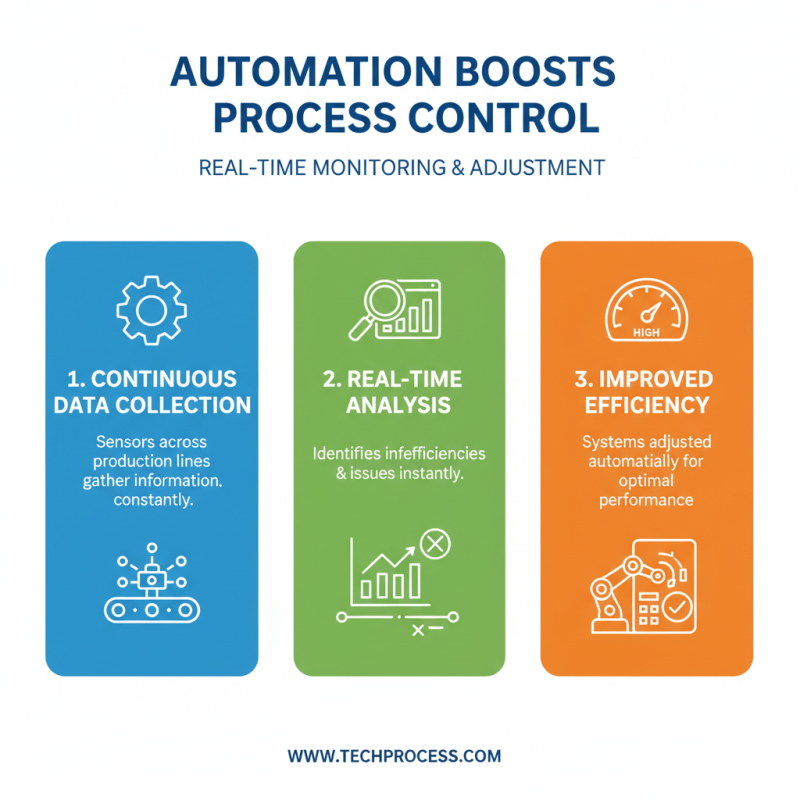

Automation technologies vastly improve process control. They help monitor and adjust systems in real time. With sensors placed throughout production lines, data is collected continuously. This data can reveal inefficiencies. It can also highlight areas needing immediate attention.

Implementing automation isn't always straightforward. Sometimes, legacy systems pose challenges. Integrating new technologies with older equipment can lead to disruptions. Additionally, training staff to manage these tools can take time. Miscommunication can happen, creating gaps in understanding.

Despite these hurdles, the potential gains are significant. Automated systems can respond quicker than human operators. This means less downtime and improved throughput. As industries strive for efficiency, the role of automation cannot be overlooked. It represents both opportunity and challenge in process control engineering.

Implementing feedback control systems can greatly enhance process efficiency. These systems adjust outputs based on real-time data. When the outcome deviates from the desired level, adjustments are made automatically. This minimizes errors and optimizes performance. However, the design phase often presents challenges. Engineers must define clear goals and accurate parameters to ensure functionality.

Data accuracy plays a crucial role. Anomalies in measurement can lead to incorrect adjustments. If sensors fail, the entire system risks malfunction. Regular maintenance and calibration are essential. Neglecting these can result in costly downtime. Operators must also be trained to interpret feedback. Misunderstanding the data can lead to bad decisions and increased inefficiencies.

Moreover, not all processes benefit equally from feedback systems. Some processes may see marginal improvements, while others become more complex. Recognizing when to implement a feedback system is essential. A thoughtful approach can make a significant difference, but it requires ongoing evaluation and refinement. Experimentation is key; it’s okay to stumble before achieving the best outcome.

Statistical Process Control (SPC) uses statistical methods to monitor and control processes. It is vital for enhancing efficiency in various industries. By identifying variations in processes, SPC helps organizations make data-driven decisions. For example, a manufacturing facility can track product dimensions. When dimensions drift from specified limits, it triggers a review. This minimizes defects and reduces waste.

Organizations often struggle to implement SPC effectively. Many teams focus too much on fixing issues instead of understanding root causes. This reactive approach can lead to recurring problems. It’s critical to engage employees in data collection. Their insights can reveal hidden trends. A culture of continuous improvement is essential for success. However, not all organizations embrace this mindset. Resistance to change can stifle progress and innovation.

Training is another challenge. Employees may feel overwhelmed by statistical tools. Simplifying these tools can enhance understanding and application. Using visual aids, like control charts, can make concepts clearer. Regularly scheduled reviews can help teams assess their progress. Engaging in open discussions fosters a reflective atmosphere. Continuous improvement requires dedication, perseverance, and a willingness to adapt.