In the rapidly evolving landscape of industrial manufacturing, the significance of manufacturing process control systems cannot be overstated. As these systems integrate advanced technologies to monitor and control production processes, they enhance efficiency, quality, and flexibility across various sectors. According to Dr. Michael Turner, a leading expert in industrial automation, "The integration of innovative digital solutions into manufacturing process control systems is the key to unlocking unprecedented levels of operational excellence and competitiveness."

As we look toward 2025, the demand for cutting-edge digital solutions in manufacturing is set to rise, reshaping the future of process control. From AI-driven analytics to IoT-enabled devices, these emerging technologies promise to optimize manufacturing processes, reduce waste, and improve decision-making through data-driven insights. The focus on sustainability and smart manufacturing is driving industry players to invest in the latest advancements, ensuring that they remain relevant in an increasingly digital world.

The importance of understanding the top digital solutions for manufacturing process control systems in the coming years is critical for manufacturers aiming to thrive in this competitive environment. As we delve into this topic, we will explore the innovations that are poised to define the future of manufacturing and the strategies that leaders in the field must adopt to harness the full potential of these technologies.

The rise of the Internet of Things (IoT) in manufacturing is revolutionizing process control systems, offering innovative solutions that enhance efficiency and responsiveness. By interconnecting a multitude of devices, IoT facilitates real-time data sharing, allowing manufacturers to monitor and optimize operations seamlessly. This transformation is particularly crucial as the global IoT in manufacturing market is projected to grow significantly, reflecting the industry's increasing reliance on advanced technological solutions for competitive advantage.

Moreover, integrating IoT with artificial intelligence (AI) is amplifying the benefits of smart manufacturing. AI algorithms analyze vast amounts of data collected from IoT devices to drive automation and predictive maintenance, significantly reducing downtime and improving overall productivity. Furthermore, initiatives like the development of IoT-based environmental monitoring systems highlight how technology can address pressing challenges within the manufacturing sector, ensuring sustainable practices while maintaining high production standards. As these innovations continue to evolve, their impact on manufacturing process control systems will become even more pronounced, ushering in a new era of operational excellence.

In the rapidly evolving landscape of manufacturing, the integration of artificial intelligence (AI) and machine learning (ML) has emerged as a transformative force in optimizing process control systems. By leveraging vast amounts of data generated during production, these technologies can identify patterns, predict equipment failures, and enhance decision-making processes. For instance, AI algorithms can analyze historical data to forecast maintenance needs, thereby reducing downtime and improving overall efficiency. This proactive approach not only saves costs but also extends the lifespan of machinery.

Moreover, the application of machine learning in quality control has revolutionized the way manufacturers ensure product standards. Through real-time monitoring and analysis, ML models can detect anomalies in production processes, allowing for immediate adjustments and minimizing defects. This capability not only enhances product quality but also fosters a culture of continuous improvement within manufacturing operations. As companies increasingly adopt these digital solutions, the synergy between AI, ML, and manufacturing will undoubtedly pave the way for more streamlined, efficient, and innovative production environments in the years to come.

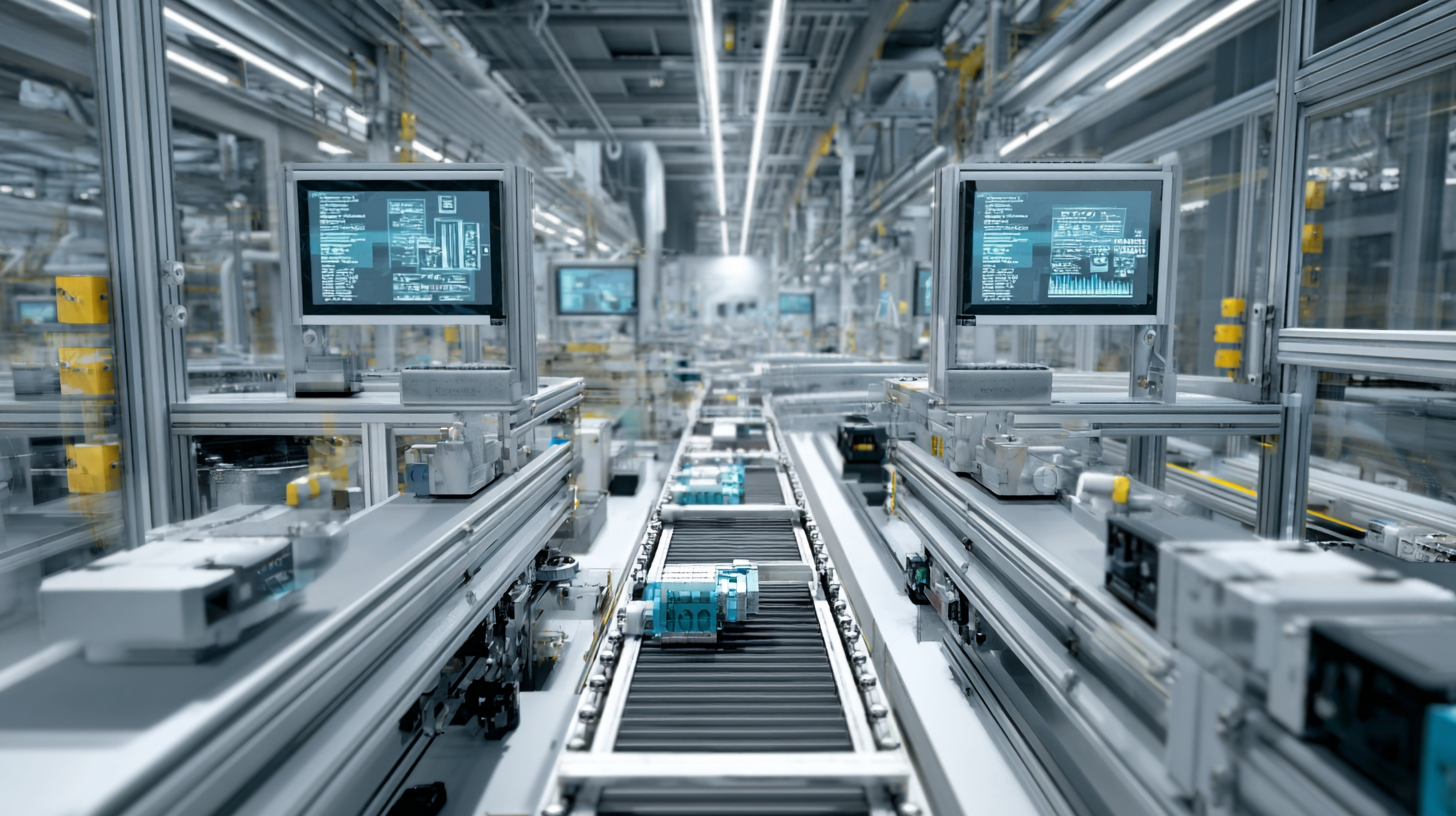

In today's fast-paced manufacturing landscape, cloud-based systems are revolutionizing process control by offering real-time monitoring and control capabilities that drive efficiency and productivity. These systems enable manufacturers to gather data from various machines and processes, allowing for instant analysis and informed decision-making. With this technology, operators can identify bottlenecks, respond quickly to anomalies, and optimize the production line all from a centralized hub, enhancing operational agility.

**Tip**: To maximize the benefits of cloud-based solutions, ensure that your data security protocols are robust. Implement multi-factor authentication and regular security audits to protect sensitive manufacturing data from cyber threats.

Furthermore, cloud-based systems facilitate seamless collaboration among teams, regardless of their physical location. With remote access to real-time data and analytical tools, cross-functional teams can work together more effectively, sharing insights and making strategic adjustments as needed. This not only improves communication but also fosters a culture of continuous improvement across the organization.

**Tip**: Invest in training programs for your team to ensure they are well-equipped to utilize these advanced systems effectively. A knowledgeable staff can leverage cloud technology to its full potential, enhancing overall productivity.

| Solution Name | Key Features | Deployment Model | Integration Capabilities | User Rating |

|---|---|---|---|---|

| CloudMonitor Pro | Real-time analytics, AI predictions | Public Cloud | API, IoT Devices | 4.5/5 |

| SmartControl 2025 | Remote monitoring, alerts | Private Cloud | ERP systems, PLCs | 4.7/5 |

| ProcessOptimizer | Data visualization, predictive maintenance | Hybrid Cloud | MES, SCM tools | 4.6/5 |

| DataInsight Suite | Batch tracking, reporting | Public Cloud | Database connectors, Cloud Storage | 4.3/5 |

As manufacturing processes increasingly rely on cloud solutions, the demand for robust cybersecurity measures has never been more critical. According to market analysis, the data protection market is projected to grow significantly, with estimates reaching a valuation of $30 billion by 2032, underlining the urgency for compliance and security in cloud environments. Companies are now prioritizing agile, fast, and flexible solutions, though they face the challenge of ensuring strong compliance frameworks and security postures to protect sensitive data.

Recent developments highlight that cybersecurity services tailored for manufacturing are gaining traction in new markets. For instance, specialized firms are offering comprehensive services including vulnerability assessments and penetration testing, which are essential for proactively identifying security weaknesses before they can be exploited. This shift emphasizes the importance of integrating cybersecurity at the core of manufacturing operations, aligning with the industry’s need for reliability and safety in an increasingly digital landscape. As businesses navigate these changes, investing in state-of-the-art cybersecurity solutions will be pivotal in safeguarding manufacturing processes from potential cyber threats.

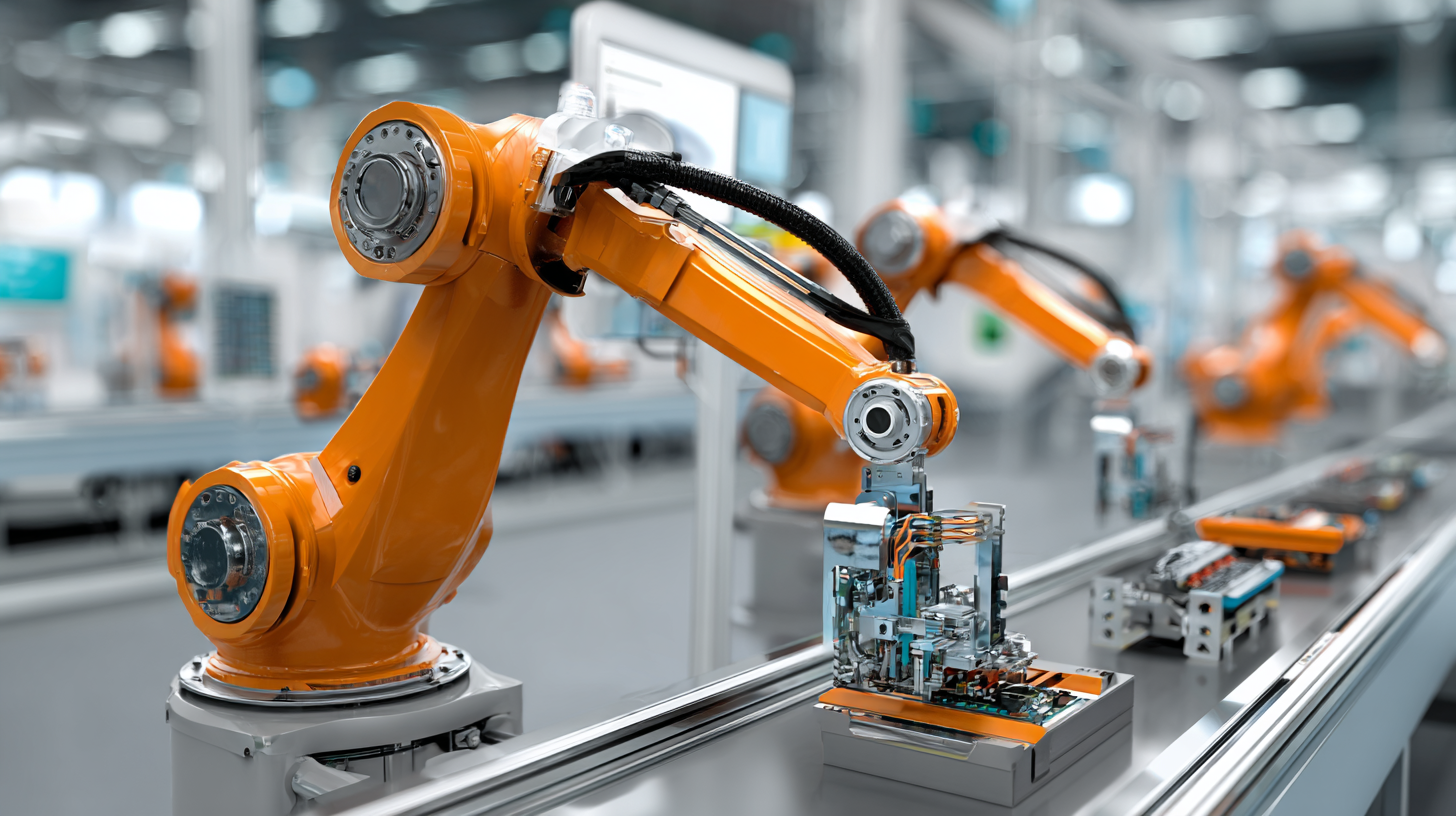

As industries increasingly pivot towards digital transformation, robotics and automation technologies emerge as pivotal elements in optimizing manufacturing process control systems. According to a report by McKinsey, companies that have adopted automation increased their productivity by 20-25%, leading to enhanced operational efficiency. These technologies not only streamline workflows but also reduce the potential for human error, which can severely impact production timelines and costs.

Additionally, the International Federation of Robotics (IFR) projects that the global market for industrial robots is poised to reach $75 billion by 2025. This growth underscores the escalating reliance on automated systems, driven by the need for faster and more precise manufacturing processes. For instance, collaborative robots (cobots) are designed to work alongside human operators, facilitating a harmonious integration that maximizes output while reducing workplace risks. By harnessing these advanced robotics solutions, manufacturers can achieve significant improvements in production scalability and adaptability, essential traits for staying competitive in the rapidly evolving market.