In today's rapidly evolving industrial landscape, organizations are increasingly recognizing the critical importance of process control training. According to a recent report by the International Society for Automation (ISA), companies that invest in comprehensive training programs experience a significant reduction in process variability and operational costs, with some studies indicating savings of up to 20%. This underscores the necessity for firms to adopt effective digital strategies for training their workforce, particularly in the realm of process control, as automation and data analytics become integral to advanced manufacturing environments.

As we look ahead to 2025, the digital transformation of process control training is set to revolutionize how industries equip their employees with essential skills. The shift toward virtual and augmented reality training methods, as highlighted in a report by the World Economic Forum, is expected to enhance learning experiences and retention rates dramatically. With a projected 45% of jobs in the manufacturing sector requiring advanced digital skills by 2030, the urgency for companies to embrace innovative training methodologies cannot be overstated. Implementing best practices in process control training will not only foster a more knowledgeable workforce but also improve overall productivity and safety in complex operational settings.

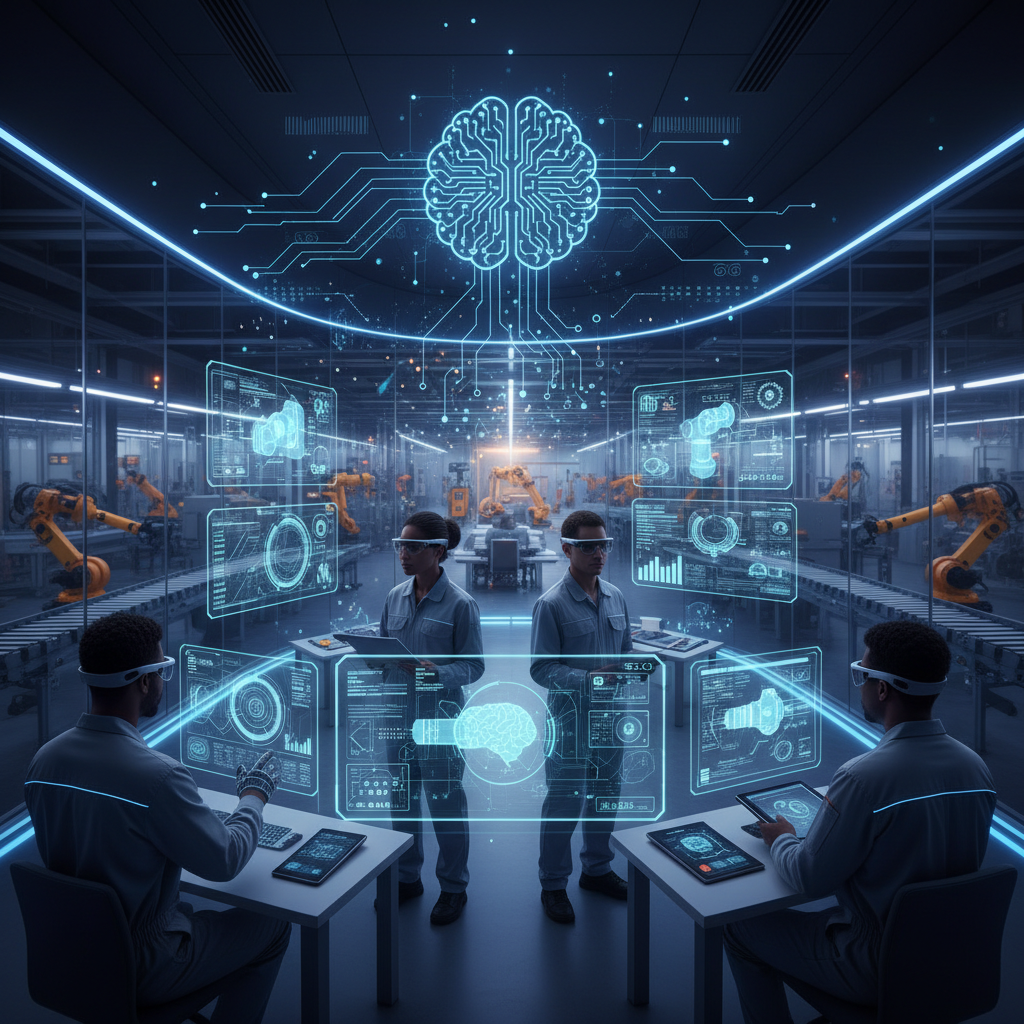

In 2025, the landscape of digital process control training is set to evolve significantly, driven by rapid technological advancements and the pressing need for efficiency. One of the foremost trends is the integration of artificial intelligence and machine learning into training programs. These technologies not only enhance the learning experience but also provide real-time data analysis and feedback, allowing trainees to grasp complex concepts more effectively. As industries increasingly adopt automated systems, the demand for skilled professionals who can navigate these advanced tools will escalate, necessitating updated training approaches.

Another key trend influencing training needs is the rise of remote and virtual learning environments. With the continual shift towards digitalization, training programs are leveraging virtual reality (VR) and augmented reality (AR) to simulate real-world operational scenarios. This immersive approach prepares trainees to handle practical challenges and improves retention by providing engaging learning experiences. Additionally, the importance of cybersecurity in digital process control cannot be overstated, prompting organizations to incorporate cybersecurity training as a core component of their programs. As these trends unfold, organizations must stay ahead by continuously adapting their training strategies to equip their workforce for a digitally-driven future.

In the rapidly evolving landscape of digital process control, future professionals must cultivate essential skills to thrive in the era of Industry 4.0. Training programs focusing on industrial intelligence are pivotal in preparing engineers and technicians for the digital transformation of manufacturing. These programs emphasize a comprehensive understanding of advanced technologies, critical thinking, and data analysis capabilities, which are vital for optimizing manufacturing processes and driving innovation.

As the demand for skilled workers in high-tech environments increases, it becomes crucial for educational institutions to adopt student-centered strategies that align with the current industry requirements. Courses that combine theoretical knowledge with hands-on experiences not only empower students to grasp complex digital tools but also enhance their adaptability in a fast-changing job market. With a strategic focus on relevant skill development, the future workforce will be better equipped to tackle the challenges posed by digital transformation, particularly in sectors demanding a seamless integration of technology and sustainable practices.

As we look toward 2025, the integration of automation and artificial intelligence (AI) in digital process control training strategies is becoming increasingly vital. AI technologies can tailor training experiences to individual learners, providing personalized feedback and adaptive learning paths. This ensures that employees not only grasp the fundamental concepts but also engage with the material in a meaningful way.

**Tip:** Leverage AI tools to analyze trainees' performance and adjust the training content accordingly. This data-driven approach allows you to identify knowledge gaps and provide targeted resources, thereby enhancing both comprehension and retention.

Furthermore, automation can streamline administrative tasks associated with training, freeing up valuable time for trainers to focus on strategic goals. Automated systems can handle scheduling, tracking progress, and even administering assessments, creating a more efficient training environment.

**Tip:** Incorporate simulation-based training environments powered by AI where employees can practice real-world scenarios in a safe space. This hands-on experience can significantly boost confidence and competence in handling complex processes.

By embracing these advancements, organizations can create more effective digital process control training strategies that not only meet the demands of the industry but also foster a culture of continuous learning and improvement.

| Training Strategy | Automation Tools | AI Integration | Expected Outcomes |

|---|---|---|---|

| Virtual Reality Simulations | VR Training Platforms | AI-Driven Feedback Analysis | Enhanced Skills Retention |

| E-Learning Modules | Learning Management Systems (LMS) | Personalized Learning Paths | Increased Engagement and Flexibility |

| On-the-Job Training with Augmented Reality | AR Headsets and Applications | Real-time Data Insights | Improved Speed and Accuracy |

| Gamified Learning Experiences | Game-Based Learning Platforms | Adaptive Learning Algorithms | Higher Completion Rates |

| Collaborative Online Workshops | Webinar Software | AI Moderators for Enhanced Interaction | Network Expansion and Shared Knowledge |

In the rapidly evolving landscape of digital process control, establishing key performance indicators (KPIs) is crucial for the success of training programs in 2025. Effective KPIs serve as benchmarks for evaluating the effectiveness of training and aligning it with organizational goals. A report by the Association for Talent Development (ATD) indicates that organizations that utilize KPIs in their training programs can achieve up to a 20% increase in overall training effectiveness. These metrics not only provide insights on employee performance but also guide the ongoing refinement of training content and delivery methods.

For training programs focused on digital process control, it's vital to consider specific KPIs such as skill acquisition rates, completion times, and post-training performance evaluations. Research from the International Society for Automation (ISA) emphasizes that organizations leveraging targeted KPIs are 35% more likely to meet their operational efficiency goals. By continuously monitoring these indicators, companies can ensure that their digital training initiatives remain relevant and impactful, fostering a workforce that is agile and proficient in the latest technologies essential for process control success.

The landscape of process control training is rapidly evolving, driven by emerging technologies such as artificial intelligence, virtual reality, and advanced data analytics. According to a recent report by Research and Markets, the global market for digital process control technology is expected to grow from $20 billion in 2022 to over $40 billion by 2027, indicating a significant shift in how companies approach training in this field. These technologies not only enhance the training experience but also improve retention and application of knowledge, creating a more skilled workforce capable of navigating complex systems.

Virtual reality (VR), in particular, is revolutionizing the way professionals are trained in process control. By simulating real-world environments, VR training allows employees to practice skills and decision-making in a risk-free space. A study from PwC indicated that VR training can lead to a 75% increase in knowledge retention compared to traditional methods. Furthermore, the integration of AI in training platforms allows for personalized learning experiences, adapting to the individual’s pace and style, which has been shown to increase engagement by 30%. As these technologies become more mainstream, organizations that invest in these innovative training strategies will find themselves at a competitive advantage in an increasingly digital world.