In today's competitive landscape, industries increasingly rely on efficient operations. An automated process control system stands out as a crucial technology. Reports indicate that over 50% of companies see improved productivity with automation.

These systems standardize processes, reduce human error, and streamline workflows. According to a recent market analysis, businesses implementing automated solutions can cut operational costs by 30%. Imagine a manufacturing line where robots enhance precision while humans focus on strategic tasks.

However, the transition to automation isn't without challenges. Many companies struggle with initial investment and employee retraining. Indeed, some may experience a temporary decline in performance during integration. Reflecting on these hurdles, it becomes clear that while the benefits are substantial, careful planning is essential for success.

Automated process control systems have become essential in modern industries. These systems enhance efficiency and improve safety in various operations. Key features include real-time monitoring and precise control. Operators can receive instant feedback, reducing reaction times significantly.

Sensors collect data continuously, allowing for informed decision-making.

Integration with existing systems is another critical feature. This enables seamless communication between different units. However, some industries may struggle with integrating new technologies. Compatibility issues can arise, often leading to frustration. User-friendly interfaces are crucial. They help operators manage systems without extensive training. Nevertheless, poor interface design can hinder effectiveness.

Predictive maintenance is integral to automated systems. Analyzing data trends can prevent equipment failures. Yet, misinterpretation of data can lead to costly mistakes. Companies must prioritize accurate data analysis for optimal performance. Automation can streamline processes, but human oversight remains vital. Balancing technology with human intuition is essential to maximize benefits.

In modern industries, automation is transforming operations. By implementing automated process control systems, companies achieve improved efficiency. These systems monitor processes in real-time. They reduce manual errors and enhance precision. As a result, production rates increase significantly. Employees can focus on more complex tasks.

Moreover, automation leads to consistent product quality. Automated systems minimize variations, ensuring that every product meets standards. However, not all industries adapt smoothly. Some workers may feel overwhelmed by new technologies. Training becomes essential to bridge this gap. Support and resources are necessary for a successful transition.

Furthermore, data collection and analysis become streamlined. Automation generates valuable insights quickly. Industries can make informed decisions based on this data. Yet, reliance on automation raises concerns about cybersecurity. Protecting sensitive information is crucial. As industries embrace automation, they must also reflect on these challenges. Balancing efficiency with security can be complex.

This chart illustrates the top benefits of implementing an automated process control system in modern industries. The data shows various advantages such as increased productivity, reduced human error, cost savings, enhanced quality control, and real-time monitoring, each represented as a percentage of importance or effectiveness in industrial operations.

Automated process control systems revolutionize manufacturing. They provide enhanced accuracy in various production stages. This technology minimizes human errors and leads to consistent product quality. Sensors and algorithms monitor processes in real-time. Any deviation from set parameters triggers immediate corrections. This precision is crucial for complex products.

However, the implementation of these systems is not always flawless. Companies may face challenges during integration. Staff may resist changing their routines. Training becomes essential to ensure everyone adapts. Moreover, initial setup costs can be significant. It requires careful assessment of long-term benefits versus short-term expenses.

Despite these hurdles, the gains in efficiency are hard to ignore. A well-implemented system ensures that products meet strict specifications. It reduces waste and increases productivity. The data gathered also aids in future improvements. As industries evolve, embracing automation is necessary. Yet, the journey needs constant evaluation and adjustments.

In modern industries, real-time data monitoring is crucial. Automated process control systems deliver instant insights into various operations. This helps companies detect issues early. Immediate alerts can prevent small problems from escalating.

Data analysis plays a significant role as well. By analyzing trends, companies can streamline production. They gain a clearer understanding of operations, which fosters better efficiency. Yet, some may struggle with interpreting this data. Visualization tools could be complex for some users, leading to misinterpretations. Training is essential.

Data accuracy is paramount. An automated system might miss anomalies during heavy processing. Relying solely on technology could lead to oversight. Human expertise should complement automation. It's a balance that industries must achieve for optimal performance.

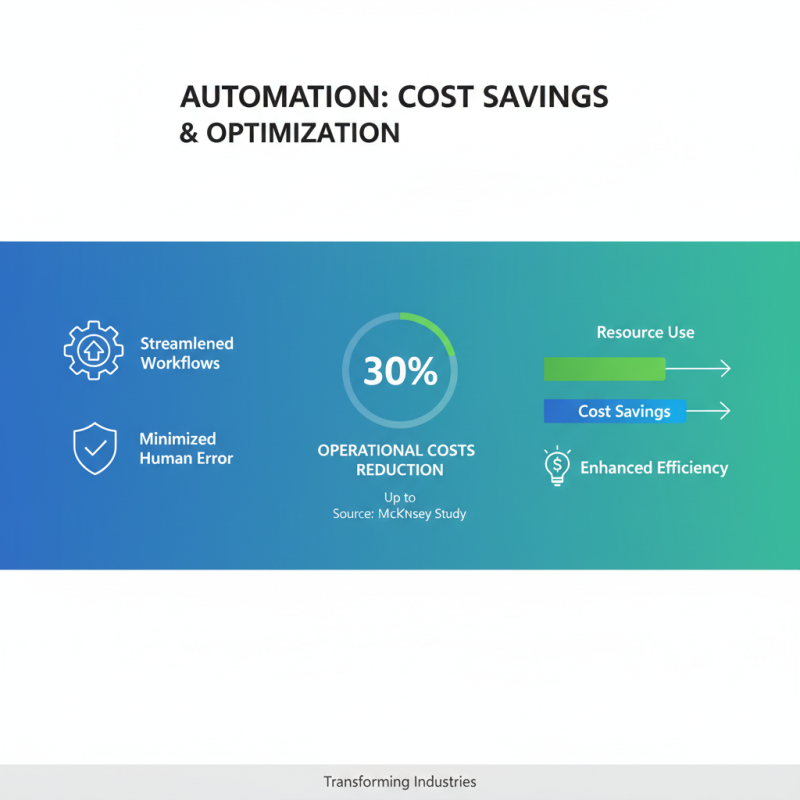

Automation is transforming industries by enhancing cost savings and optimizing resource use. A recent study by McKinsey observed that companies implementing automated process control systems can reduce operational costs by up to 30%. This substantial saving is often achieved through streamlined workflows and minimized human error.

Furthermore, the reduction in labor costs is significant. According to a report from Deloitte, automation can lead to a 50% decrease in labor hours for processes that are repetitive and time-consuming. This not only frees up human resources for more strategic tasks but also maximizes productivity. However, businesses should be cautious. Implementing automation without proper planning can lead to productivity bottlenecks.

Data from PwC indicates that 45% of current jobs are susceptible to automation. This statistic prompts a critical reflection on workforce training and development. Companies must ensure employees can adapt alongside automation technologies. Striking a balance between efficiency and employee capability is essential for sustainable growth in an increasingly automated landscape.