In today's fast-paced industrial landscape, automation controls are essential for maximizing efficiency. Renowned expert Dr. Emily Carter states, "Effective automation controls can revolutionize processes." This insight captures the spirit of innovation driving modern industries toward increased productivity.

The rise of automation controls is reshaping how businesses operate. Manufacturers, for instance, leverage smart technologies to streamline production lines. However, many industries still grapple with implementation challenges. The gap between understanding automation and applying it effectively remains significant.

Numerous companies have struggled with integrating automation controls seamlessly, leading to inconsistent results. It's crucial to recognize that while automation offers immense potential, it also requires careful consideration. Industries must reflect on their specific needs and capabilities before fully adopting automation strategies.

Automation controls have transformed modern industries, making their operations more efficient. These controls enable precise monitoring and management of processes. For example, sensors collect real-time data on machinery performance. This data helps companies identify inefficiencies quickly. However, not all systems integrate perfectly. Compatibility issues can arise, causing disruptions.

Another critical aspect of automation is its impact on the workforce. While many tasks become automated, human oversight remains essential. Employees must adapt to new technologies. Some may struggle with this transition, highlighting the need for ongoing training. Additionally, reliance on automation can lead to complacency. Regular evaluations of automated systems are crucial to maintain efficiency.

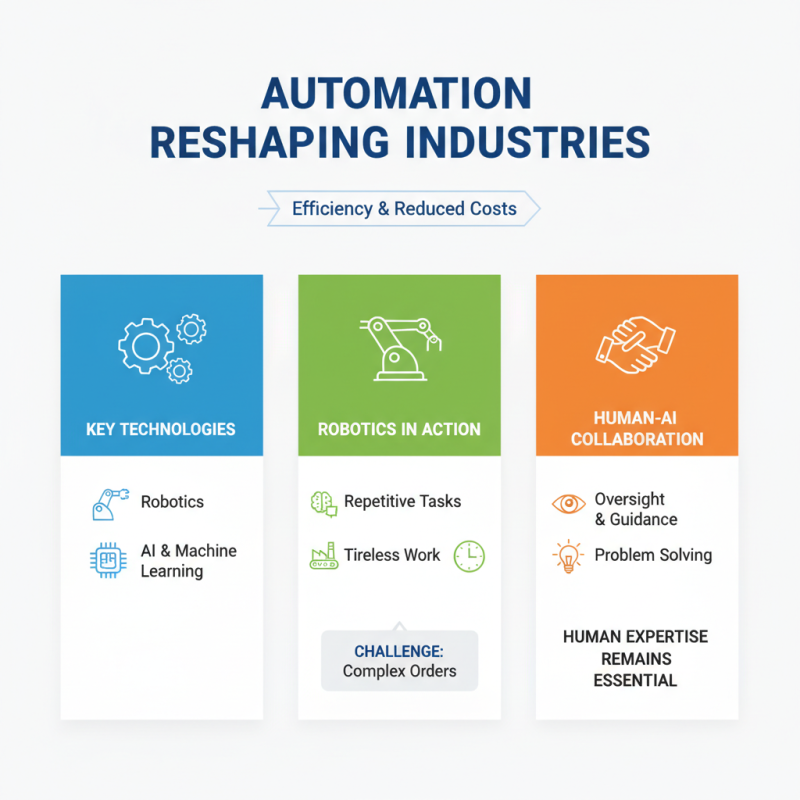

In manufacturing, automation controls streamline production lines. Robotics can handle repetitive tasks with speed and accuracy. Yet, they cannot replace human creativity and problem-solving skills. These limitations remind industries that technology should complement human input. Balancing automation with a skilled workforce is vital for long-term success.

| Control Type | Key Features | Benefits | Applications |

|---|---|---|---|

| Programmable Logic Controllers (PLCs) | Real-time processing, flexibility, and reliability | Improved process control and reduced downtime | Manufacturing automation, robotics |

| Human-Machine Interfaces (HMIs) | User-friendly visual displays and controls | Enhanced user experience and quick decision-making | Control rooms, monitoring stations |

| Distributed Control Systems (DCS) | System-wide control, redundancy, and scalability | Reliable operations and centralized control | Process industries, chemical plants |

| Supervisory Control and Data Acquisition (SCADA) | Real-time data collection and monitoring | Improved operational insight and remote supervision | Utilities, water treatment |

| Industrial Internet of Things (IIoT) | Connectivity and data exchange among devices | Enhanced predictive maintenance and process optimization | Manufacturing, logistics |

| Robotic Process Automation (RPA) | Automation of rule-based tasks | Increased efficiency and reduced operational costs | Finance, HR, customer service |

| Machine Learning Algorithms | Data pattern recognition and predictive analytics | Enhanced decision-making capabilities | Quality control, supply chain management |

| Digital Twins | Virtual replicas of physical systems | Improved design and operational efficiencies | Product testing, equipment maintenance |

| Cloud-based Automation | Remote monitoring and control through the cloud | Scalability and cost-effectiveness | Various industrial applications |

Automation controls play a vital role in modern industries. They optimize processes and elevate efficiency. Implementing these controls leads to numerous benefits. One key advantage is improved operational consistency. Automation enables machines to perform repetitive tasks flawlessly. This reduces human error and increases output. Employees can focus on more strategic activities.

Moreover, automation enhances data accuracy. It allows real-time monitoring of processes. This immediacy helps in making informed decisions. Quick adjustments can be made based on current data. Even minor errors in data collection can lead to significant issues later.

Yet, there are challenges to consider. Integration with existing systems can be complex. Employees may resist changes or fear job loss. It’s crucial to provide training and support during the transition. Companies must reflect on these issues to ensure smooth implementation. Automation controls hold great potential, but success depends on thoughtful execution.

Automation is reshaping industries by improving efficiency and reducing costs. Key technologies are driving this transformation. Robotics plays a major role, handling repetitive tasks. These machines work tirelessly, but they can struggle with complex orders. Human oversight remains essential to guide them effectively.

Artificial intelligence enhances decision-making. AI systems analyze vast data quickly, revealing trends. This speed is impressive, but errors can arise from faulty data. Regular audits are essential to maintain accuracy. Moreover, machine learning adapts processes, optimizing production. However, changes can lead to initial disruptions, requiring adjustments.

Internet of Things (IoT) enhances connectivity among devices. Sensors gather real-time data, allowing for quick responses. Without proper integration, however, issues may arise. Systems may malfunction, leading to downtime. Overall, the path to automated efficiency is filled with both promise and challenges.

Choosing the right automation controls is not straightforward. Many factors influence decision-making. Understanding the unique needs of an industry is vital. Different sectors have varying levels of complexity. For instance, manufacturing needs precision, while logistics requires speed. Assessing these specific requirements leads to better performance.

Integration compatibility is another critical factor. Automation systems must work seamlessly with existing technologies. If not, it can lead to disruptions. Simple interfaces are often more ideal than overly complex systems. Employees may struggle to adapt to intricate setups. Training can become a significant hurdle. Balancing ease of use and functionality is an ongoing challenge.

Cost-effectiveness also plays a crucial role in selection. Initial investment can be significant, yet return on investment is key. It’s essential to calculate long-term savings. Some systems promise high efficiency but fail to deliver over time. Companies should be wary of over-promising solutions. Conducting a pilot test helps to mitigate risks. Collect feedback and evaluate performance closely. This reflection aids in choosing the right tools for efficiency.

Many industries are leveraging automation to boost efficiency. The manufacturing sector, for instance, has seen substantial gains. According to a report by McKinsey, companies that adopted automation improved productivity by 20-50%. A case study in a steel plant revealed that automated machinery reduced error rates. This led to significant cost savings and faster production times.

In the healthcare sector, automation also plays a critical role. A study showed that automated patient management systems increased hospital efficiency by 30%. However, implementing such systems is not without challenges. Staff training and system integration often take longer than anticipated. Sometimes, these transitions lead to disruptions, which can affect service delivery.

Retail businesses have also tapped into automation. A report indicated that automated inventory systems can reduce stock discrepancies by up to 40%. Yet, striking a balance between automation and human oversight remains crucial. Some retailers have struggled with fully relying on automated systems, leading to customer dissatisfaction. Learning from these challenges is key for future success.