In an era where efficiency is key, automated process control systems are transforming industries. These systems streamline operations and reduce human error. Understanding the different types of automated process control can enhance productivity and improve quality.

Many companies have adopted automated process control for better consistency. Industries like manufacturing and energy heavily rely on these systems. However, not all systems are maintained equally. Some can lead to unexpected challenges. Issues like system integration and user training need attention.

Investing in these technologies can yield great returns. But companies must choose wisely. The wrong choice may hinder growth and adaptation. In this landscape, knowing the top automated process control systems is crucial for staying competitive.

Automated process control systems play a crucial role in various industries, from manufacturing to energy. According to recent studies, over 70% of industrial operations utilize these systems to enhance efficiency. These technologies monitor and manage processes in real-time, ensuring optimal performance and reduced downtime. They analyze vast amounts of data, offering insights that lead to informed decision-making.

The market for automated process control systems is projected to grow significantly. A report from a leading research firm indicates a compound annual growth rate (CAGR) of nearly 8% over the next five years. Despite the advancements, many organizations struggle with integration. Legacy systems can hinder progress, leading to inefficiencies and increased costs. Additionally, human oversight can introduce errors, even in automated environments.

Maintenance is another area that requires attention. While automation minimizes manual work, it does not eliminate the need for regular checks and updates. In fact, neglecting system upkeep can lead to failures. A survey found that 40% of companies experience unplanned downtime due to maintenance issues. This highlights the need for continuous evaluation and adaptation as technology evolves.

| System Name | Key Features | Applications | Industry | Deployment Type |

|---|---|---|---|---|

| System A | Real-time monitoring, predictive analytics | Chemical processing, Oil refining | Chemical Industry | Cloud-based |

| System B | Advanced control algorithms, Batch processing | Pharmaceutical manufacturing | Pharmaceutical Industry | On-premise |

| System C | Scalability, Integration with ERP | Food and beverage processing | Food Industry | Hybrid |

| System D | User-friendly interface, Data visualization | Water treatment | Environmental Industry | Cloud-based |

| System E | Remote monitoring, Customizable dashboards | Energy management | Energy Sector | On-premise |

| System F | High availability, Fault tolerance | Automotive manufacturing | Automotive Industry | Hybrid |

| System G | Data analytics, Simulation | Pulp and paper production | Forestry Industry | Cloud-based |

| System H | Predictive maintenance, Energy efficiency | Mining operations | Mining Industry | On-premise |

| System I | Multi-site control, Data sharing | Textile manufacturing | Textile Industry | Cloud-based |

| System J | AI integration, Adaptable controls | Metal processing | Metallurgical Industry | Hybrid |

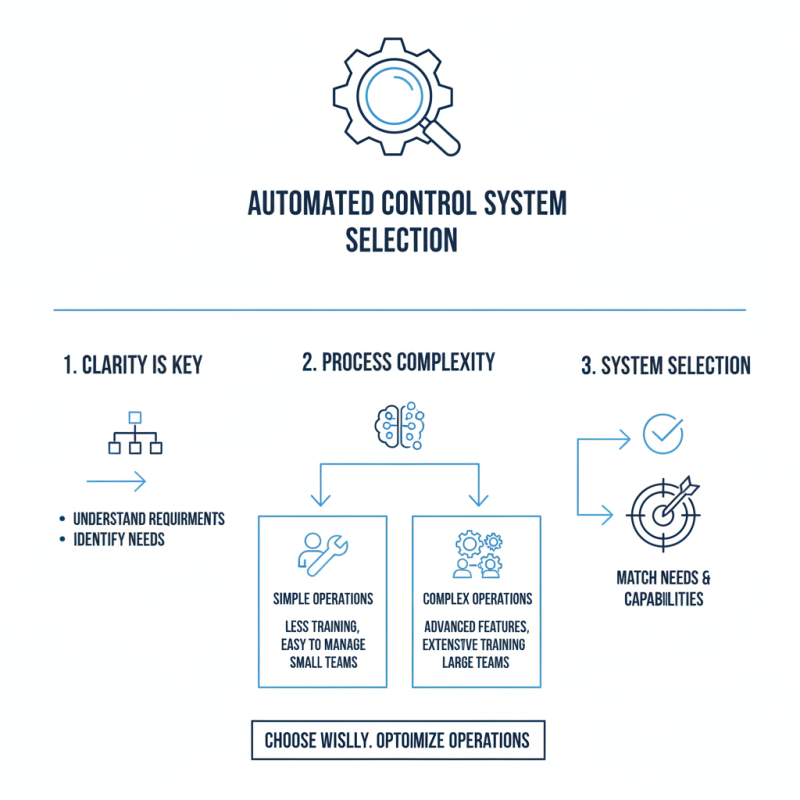

When selecting an automated control system, clarity is key. A clear understanding of your process requirements is essential. It helps to identify what you really need. Consider the complexity of your operations. Simpler systems often require less training. They can be easier to manage, especially for small teams.

Another important factor is scalability. The system should adapt as your operations grow. What works today may not suffice tomorrow. Flexibility in adjusting to changing demands is crucial. User interface should be intuitive. Unwieldy interfaces can lead to mistakes. It's vital that operators feel comfortable navigating the system, even during stress.

Finally, think about integration. The new system should work well with existing tools. Integration challenges can create complications. Assessing compatibility upfront saves time later. Each decision carries weight, and sometimes overlooked details can disrupt entire processes. Reflecting on these criteria is essential for long-term success.

Automated process control systems play a crucial role in modern industries. They enhance efficiency and ensure consistent output. These systems manage complex processes in manufacturing, oil refining, and chemical production, among others. Each system varies in capabilities, catering to specific industry needs.

When considering a control system, it’s essential to focus on scalability. Systems should adapt easily to changes in production volume. Additionally, usability is vital. Operators must navigate the interface with ease. A user-friendly design can reduce training time significantly.

Tips: Regular system updates are necessary. Outdated software can lead to vulnerabilities. Also, don't overlook the importance of troubleshooting procedures. Staff should be trained to identify problems early. Keeping a log of frequent issues can help in fine-tuning the system.

Moreover, integration with existing machinery is critical. A new system should work seamlessly with what is already in place. This can sometimes be a challenge. Some systems may require extensive modifications, adding to the project's cost. Keep this in mind when planning upgrades or replacements.

Automated process control systems have transformed industries. Different systems come with unique advantages and specific applications. Understanding these differences is crucial for making informed choices.

One notable advantage of some systems is their ability to enhance precision. They can optimize process variables for consistency. However, not all systems excel in flexibility. Some may struggle in dynamic environments where adaptability is key. For instance, certain setups might require manual intervention during unexpected changes. This could lead to delays and inefficiencies.

Another factor to consider is cost-effectiveness. Some systems offer lower initial investment. Yet, they might lead to higher operational costs over time. In contrast, advanced systems may have higher upfront costs but save money in the long run through efficiency. Choosing the right solution involves weighing these trade-offs. It's not always a straightforward decision. Different industry needs can complicate the process.

Automation and process control technology are rapidly evolving. New trends emerge frequently, showing us the direction of the future. One key trend is the integration of artificial intelligence. AI can optimize processes in real time. It analyzes data patterns, improving efficiency.

Another trend is the rise of advanced sensors. These devices capture precise measurements in various environments. Their data ensures systems operate smoothly and safely. However, the challenge lies in data overload. Too much information can complicate decision-making.

Cloud computing is also changing the landscape. It offers scalable solutions for data storage and analysis. With this technology, teams can access data remotely, fostering collaboration. Yet, security remains a concern. As companies transition to the cloud, they must prioritize data protection. Balancing innovation and safety is crucial for future success.