In the rapidly evolving landscape of modern industry, automation contractors play a pivotal role in driving efficiency and innovation. As companies seek to streamline operations and enhance productivity, the expertise of automation contractors becomes indispensable. According to John Smith, a leading expert in automation solutions, "The integration of advanced automation technologies is crucial for businesses aiming to stay competitive in today's market." This statement underscores the significance of automation contractors in facilitating the adoption of these technologies.

Automation contractors not only provide the technical know-how necessary for implementing sophisticated systems but also offer tailored solutions that meet the unique needs of various industries. Their ability to design, install, and maintain automated systems ensures that businesses can optimize their workflows and reduce operational costs. As industries continue to embrace automation in pursuit of greater efficiency, the contributions of automation contractors will only become more pronounced, solidifying their role as key players in the transformation of modern industry.

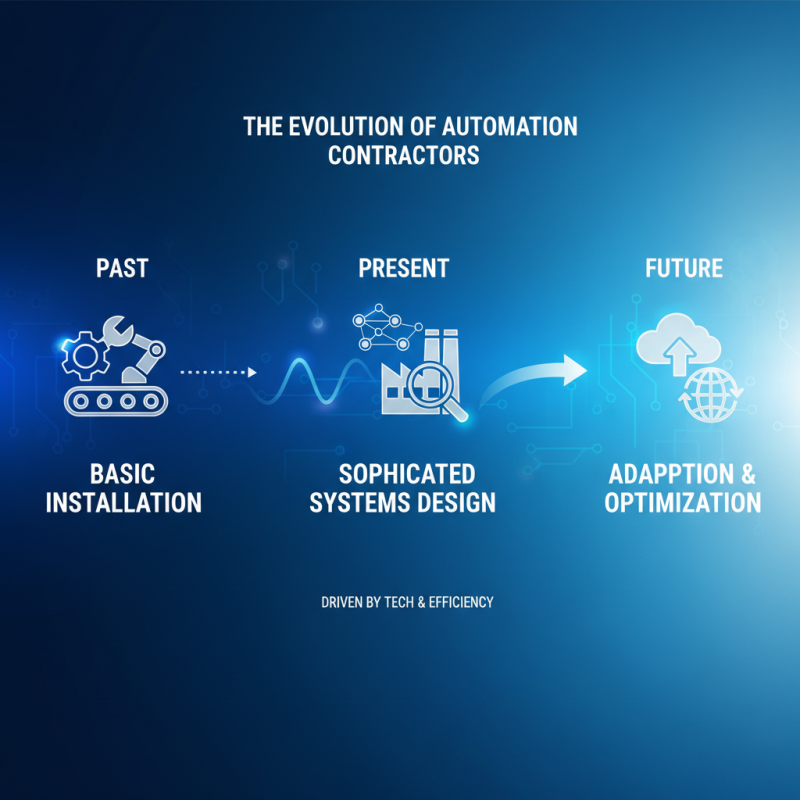

The evolution of automation contractors in industrial settings has been marked by significant advancements driven by technological innovations. Initially, these contractors focused primarily on the installation of basic machinery and assembly lines. However, as industries began to recognize the importance of efficiency and precision, the role of automation contractors expanded considerably. Nowadays, they are integral to designing, implementing, and maintaining sophisticated automation systems that enhance productivity and reduce operational costs. This shift has allowed manufacturers to adapt faster to market demands while maintaining high-quality standards.

As automation technology continues to advance, the skill set of automation contractors has evolved accordingly. They are now required to have a deep understanding of robotics, artificial intelligence, and system integration. This technical proficiency not only enables them to install automated solutions effectively but also to troubleshoot and optimize these systems for better performance. Furthermore, contractors often collaborate with engineers and software developers to tailor solutions that cater to specific industry needs, showcasing their role as vital partners in innovation.

**Tips:** When considering the adoption of automation in your industrial setting, engage with experienced contractors who can provide insights tailored to your specific needs. Additionally, staying updated on the latest technologies and industry trends will empower you to make informed decisions about your automation strategies. Lastly, fostering a collaborative environment between your in-house team and automation contractors can enhance project outcomes and lead to more innovative solutions.

Automation contractors play a pivotal role in modern industry, particularly in the realm of process optimization. They are the specialists who design, implement, and maintain automated systems tailored to enhance operational efficiency. By integrating advanced technologies such as robotics, artificial intelligence, and data analytics into existing processes, these contractors help organizations streamline workflows, reduce manual errors, and ultimately increase productivity. Their expertise enables companies to respond swiftly to market demands while minimizing downtime and operational costs.

Tips for businesses looking to engage automation contractors include a thorough assessment of current processes to identify inefficiencies and opportunities for improvement. Clear communication of goals and expectations is crucial to ensure that the contractor's solutions align with the company's vision. Moreover, fostering a collaborative relationship with automation professionals can lead to tailored solutions that suit specific industry needs. Continuous evaluation of the implemented systems post-automation is also essential to adapt to changing requirements and to maximize the ongoing benefits of the automation.

In addition, training staff to work alongside automated systems is vital for a smooth transition. Employees equipped with knowledge about the new technologies are more likely to embrace change and contribute positively to the optimization process. By taking these steps, companies can effectively harness the full potential of automation contractors, driving significant advancements in their operations.

The integration of automation in modern industry has significantly transformed labor markets and workforce dynamics. According to a report from the World Economic Forum, automation is expected to displace 85 million jobs by 2025, while simultaneously creating 97 million new roles that are more adapted to the new division of labor between humans and machines. This shift indicates a pressing need for workers to acquire new skills, particularly in technology and data analysis, as traditional roles decline in popularity.

Moreover, the 2021 Deloitte Insights study highlighted that sectors such as manufacturing, logistics, and services are experiencing the most significant impacts from automation. The study revealed that companies adopting automation technologies can achieve productivity increases of up to 30%. However, as industries implement more advanced automation solutions, there is a growing concern regarding job polarization, where higher-skilled jobs become more prevalent while lower-skilled positions vanish or are significantly reduced. This transition necessitates a strategic approach to workforce development, focusing on reskilling and upskilling initiatives to ensure that employees remain relevant in a rapidly changing job landscape.

Moreover, the 2021 Deloitte Insights study highlighted that sectors such as manufacturing, logistics, and services are experiencing the most significant impacts from automation. The study revealed that companies adopting automation technologies can achieve productivity increases of up to 30%. However, as industries implement more advanced automation solutions, there is a growing concern regarding job polarization, where higher-skilled jobs become more prevalent while lower-skilled positions vanish or are significantly reduced. This transition necessitates a strategic approach to workforce development, focusing on reskilling and upskilling initiatives to ensure that employees remain relevant in a rapidly changing job landscape.

Automation contractors play a pivotal role in revolutionizing modern industries by implementing advanced technologies that enhance efficiency and productivity. Numerous case studies illustrate their successful integration of automation systems across various sectors. For instance, in the manufacturing industry, one contractor streamlined the production process of an automotive plant by installing robotic assembly lines. This not only increased throughput but also reduced manufacturing costs and minimized human error, showcasing the potential of automation to transform traditional practices.

Another notable example can be found within the food processing sector, where a contractor designed and implemented an automated packaging line. By incorporating sensors and AI-driven systems, the contractor enabled real-time quality control and faster product throughput. This integration greatly improved the company's ability to meet consumer demand and adapt to market fluctuations. Such case studies highlight the significant impact that automation contractors can have on operational efficiency, demonstrating that their expertise is crucial for businesses aiming to thrive in an increasingly automated market landscape.

In the realm of smart manufacturing, automation contractors are becoming pivotal players, ensuring that businesses can leverage technology to optimize productivity and efficiency. According to a report by McKinsey, the potential for automation in manufacturing could increase productivity by up to 30%, allowing companies to achieve more with fewer resources. This transformation is not merely about adopting new tools; it requires a complete overhaul of processes, systems, and workforce roles, elevating the importance of skilled automation contractors who can guide organizations through this transition.

One of the future trends in smart manufacturing is the integration of IoT (Internet of Things) technologies, which enhances machine-to-machine communication and data collection. A report from Gartner predicts that by 2025, more than 75% of organizations will have migrated to cloud-based systems, laying the groundwork for real-time analytics and automated decision-making. Automation contractors are essential in implementing these technologies, ensuring that systems work harmoniously, and providing ongoing support as industries evolve.

Tips: