In today's fast-paced industrial landscape, the need for enhanced efficiency and productivity has never been more critical. Manufacturing process automation is at the forefront of this transformation, offering innovative solutions that streamline operations and reduce costs.

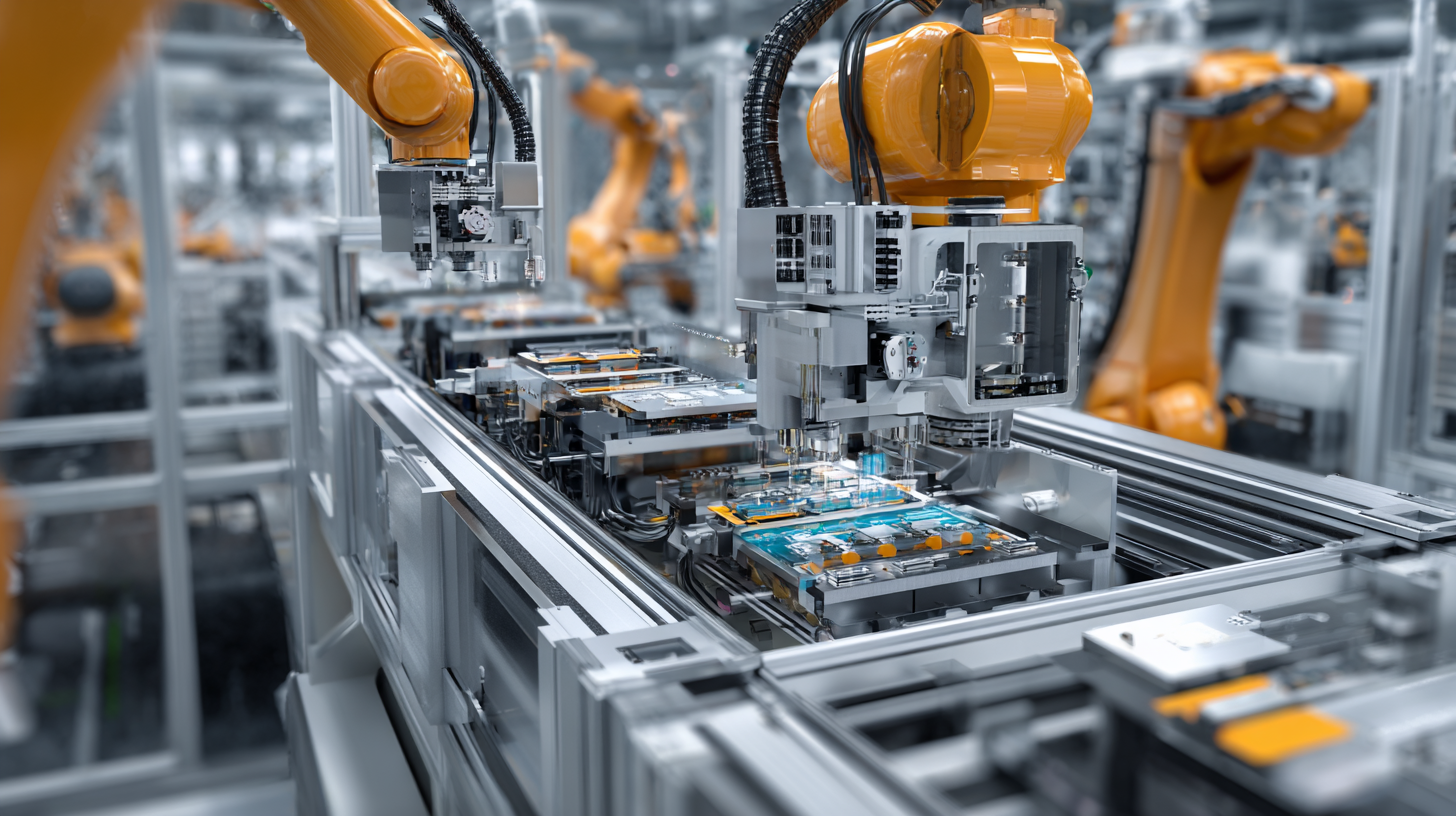

By integrating advanced technologies such as robotics, artificial intelligence, and the Internet of Things (IoT), companies can automate repetitive tasks, improve accuracy, and accelerate production cycles. This shift not only optimizes resource allocation but also elevates workforce capabilities, allowing employees to focus on higher-value tasks that drive strategic growth.

As industries evolve, the implementation of manufacturing process automation emerges as a key driver in overcoming challenges and unlocking new opportunities for sustainable success. This article aims to explore the myriad ways in which manufacturing process automation is revolutionizing efficiency, ensuring that modern industries remain competitive in an ever-changing market.

By integrating advanced technologies such as robotics, artificial intelligence, and the Internet of Things (IoT), companies can automate repetitive tasks, improve accuracy, and accelerate production cycles. This shift not only optimizes resource allocation but also elevates workforce capabilities, allowing employees to focus on higher-value tasks that drive strategic growth.

As industries evolve, the implementation of manufacturing process automation emerges as a key driver in overcoming challenges and unlocking new opportunities for sustainable success. This article aims to explore the myriad ways in which manufacturing process automation is revolutionizing efficiency, ensuring that modern industries remain competitive in an ever-changing market.

The integration of manufacturing process automation has significantly transformed production efficiency across modern industries. By minimizing manual intervention, automation technologies streamline processes, reduce errors, and enhance throughput. This shift not only accelerates production schedules but also allows for real-time data monitoring, enabling manufacturers to make informed decisions swiftly. Companies leveraging automation can achieve a high level of consistency and quality in their products, leading to improved customer satisfaction and loyalty.

Tip: To maximize the impact of automation, assess your current workflows and identify areas that benefit most from automation. Focus on repetitive tasks that can be easily streamlined to see the fastest gains in efficiency.

Moreover, automation offers scalability that is crucial in today’s dynamic market environment. With the ability to adjust operations quickly in response to demand fluctuations, businesses can maintain their competitive edge. Implementing advanced robotics and AI-driven systems paves the way for innovative practices, further driving efficiency.

Tip: Always invest in employee training programs alongside automation implementation. Upskilling your workforce ensures that they can handle the new technologies effectively, thus enhancing overall productivity.

Manufacturing process automation is rapidly changing the landscape of modern industries, primarily driven by key technologies such as digital twin technology. By utilizing enhanced simulation design and high-resolution modeling, artificial intelligence (AI) makes precise manufacturing processes more feasible than ever. This innovation supports a range of applications, including product design, maintenance optimization, and process efficiency, ultimately contributing to lower costs and higher productivity in manufacturing.

Tips: Implementing digital twin technology can lead to significant improvements in operational performance. Organizations should focus on integrating AI-driven insights into their existing workflows to maximize the benefits of automation. Moreover, fostering a culture of continuous improvement can help teams adapt and leverage these advancements effectively.

The growth of the industrial automation market is evident, with expectations of a substantial increase in market size over the coming years. Key sectors such as electronic design automation and smart manufacturing are at the forefront of this transformation. Companies that invest in advanced control and data application technologies can anticipate a competitive edge and evolve alongside industry trends.

The integration of manufacturing process automation has proven to be a game changer across various industries. In the automotive sector, for example, companies have adopted robotic assembly lines that not only enhance precision but also significantly reduce production time. A notable case study involves a leading car manufacturer that implemented automated painting systems, resulting in a 30% decrease in waste and a 25% increase in throughput. This shift not only optimized resource usage but also improved product quality, setting a new standard for efficiency.

In the food and beverage industry, automation has streamlined processes from packing to quality control. A food processing plant, for instance, adopted machine learning algorithms to monitor and control production lines. This implementation led to an impressive reduction in downtime and a marked improvement in product consistency. By leveraging data analytics, the facility achieved a 15% increase in overall efficiency while minimizing errors in packaging.

**Tips for Successful Automation:**

1. Start small by automating one segment of your process to measure impact before scaling.

2. Invest in staff training to ensure that your team is well-equipped to manage and maintain new automation technologies.

3. Continuously evaluate and adjust your systems based on performance data to maximize effectiveness.

The implementation of manufacturing process automation presents numerous challenges that organizations must navigate to enhance efficiency. One significant hurdle is the skills gap, where a shortage of trained personnel limits the adoption of advanced automation technologies. Companies are compelled to invest in workforce development and retraining programs to bridge this gap, ensuring employees are equipped to work alongside sophisticated automation systems.

Moreover, deploying automation often requires a cultural shift within organizations. Resistance to change can impede progress, making it essential for leadership to foster a culture that embraces innovation and adaptability. Strategies such as effective communication about the benefits of automation and involving employees in the transition process can mitigate resistance. As firms leverage AI-powered solutions to streamline operations, addressing these challenges becomes critical in realizing the full potential of manufacturing automation and driving sustainable practices in the industry.

The landscape of industrial automation is rapidly evolving, driven by advancements in technology and the growing demand for efficiency. Future trends indicate a significant shift toward the integration of artificial intelligence (AI) and machine learning into manufacturing processes. These technologies enable predictive maintenance, reducing downtime, and improving operational efficiency. By analyzing data in real-time, companies can anticipate equipment failures and optimize production schedules, ensuring a smoother workflow and reducing costs.

Another notable trend is the increased adoption of collaborative robots, or cobots, which work alongside human operators to enhance productivity. These robots are designed to perform specific tasks without the need for extensive safety measures, allowing for greater flexibility on the production floor. As industries embrace this synergy between humans and machines, we can expect a transformation in job roles, where workers focus more on supervisory and advanced operational tasks, thereby enhancing overall workplace efficiency.

Moreover, the rise of the Internet of Things (IoT) is facilitating smarter factories that can monitor and manage processes remotely. By connecting machines to a centralized system, manufacturers can gain insights into every aspect of their operations, from supply chain management to customer feedback. This interconnectedness not only streamlines processes but also fosters a culture of continuous improvement, paving the way for a new era of efficiency in industrial automation.