In the rapidly evolving landscape of manufacturing, the integration of process control and automation has emerged as a game-changer, driving significant productivity gains across various industries. As organizations strive to enhance efficiency and streamline operations, the adoption of advanced technologies and methodologies becomes imperative. This comprehensive guide will delve into how process control and automation not only optimize workflows but also foster innovation and adaptability in production processes. By implementing these cutting-edge solutions, manufacturers can achieve remarkable improvements in output and resource management, ultimately leading to an impressive 30% increase in productivity. Join us as we explore effective strategies and best practices that can help organizations leverage process control and automation to revolutionize their manufacturing operations.

In the rapidly evolving landscape of manufacturing, leveraging process control has emerged as a cornerstone for optimized manufacturing solutions. Recent studies indicate that industries implementing advanced process control techniques have experienced productivity gains of up to 30%. According to a report by McKinsey & Company, manufacturers employing these technologies see reduced cycle times and enhanced product quality, ultimately translating to significantly higher profit margins.

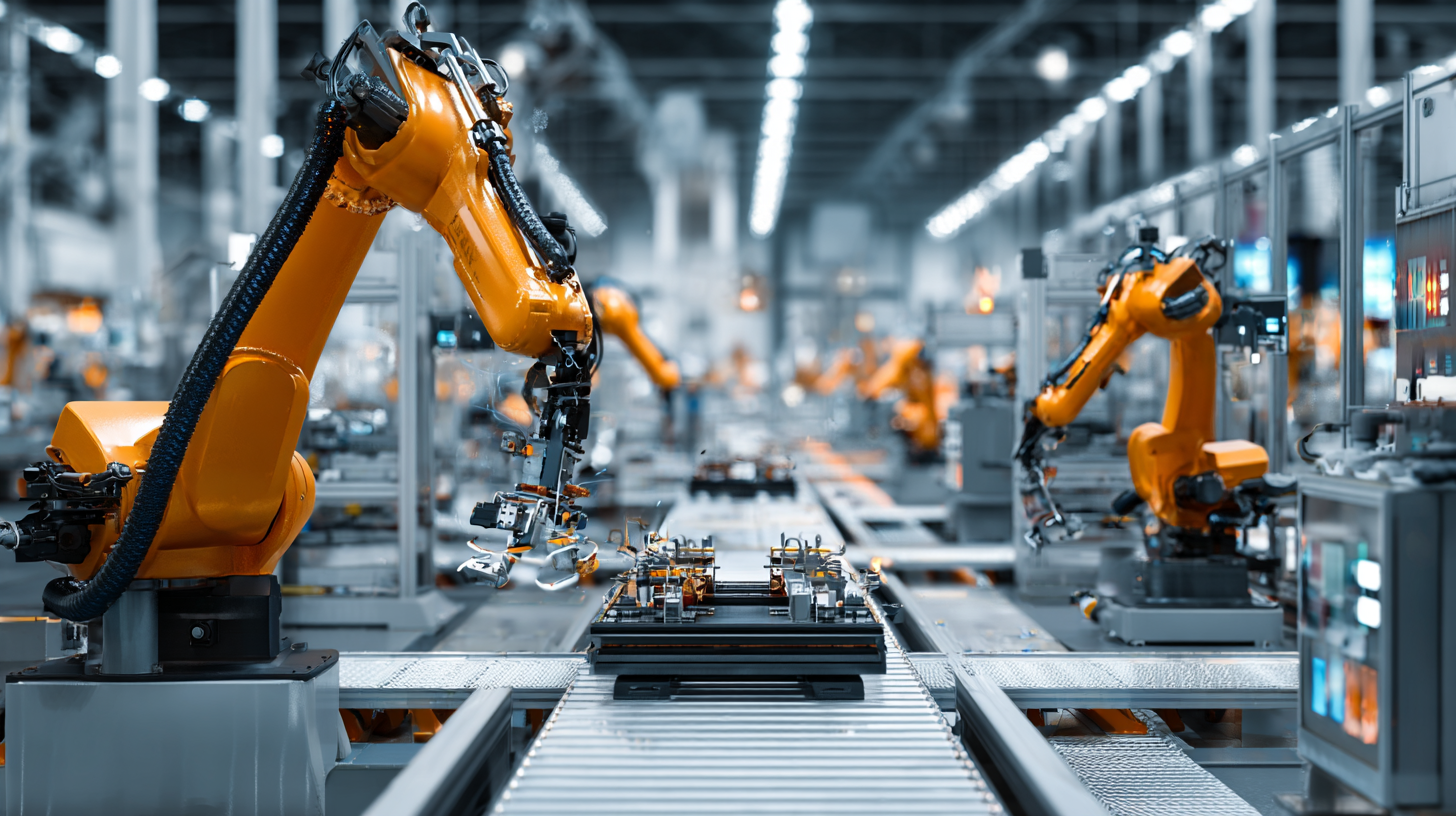

Automation further amplifies these benefits by streamlining operations and minimizing human error. The International Federation of Robotics (IFR) notes that the use of industrial robots in manufacturing can increase output by 20% or more. This synergy between automation and process control facilitates real-time monitoring and adjustments, ensuring that production processes are not only efficient but also responsive to changes in demand and operational conditions. As such, manufacturers that embrace these innovations are not just improving efficiency; they are positioning themselves for sustainable growth in an increasingly competitive marketplace.

Integrating automation technologies into manufacturing processes is proving to be a game-changer for productivity and efficiency. According to a report by McKinsey & Company, manufacturers that fully embrace automation can see productivity gains of up to 30%. This is largely due to advancements in

robotics, artificial intelligence, and the Internet of Things (IoT), which facilitate streamlined operations and data-driven decision-making. For instance, manufacturers leveraging IoT technologies can monitor machine performance in real-time, predict maintenance needs, and thus minimize downtime.

Integrating automation technologies into manufacturing processes is proving to be a game-changer for productivity and efficiency. According to a report by McKinsey & Company, manufacturers that fully embrace automation can see productivity gains of up to 30%. This is largely due to advancements in

robotics, artificial intelligence, and the Internet of Things (IoT), which facilitate streamlined operations and data-driven decision-making. For instance, manufacturers leveraging IoT technologies can monitor machine performance in real-time, predict maintenance needs, and thus minimize downtime.

Moreover, a study from the International Federation of Robotics indicates that the global industrial robot stock reached 2.7 million units by 2020, with a projected annual growth of 12% through 2025. This growing adoption of robotics is enabling factories to operate with greater precision and speed. As automated systems take over repetitive tasks, human workers are freed to focus on more complex problem-solving and innovation, further enhancing overall productivity. By integrating these cutting-edge automation technologies, manufacturers are not only maximizing production efficiency but also setting the stage for sustainable growth in a rapidly evolving industry landscape.

In an increasingly competitive manufacturing landscape, data-driven decision-making has emerged as a critical component for enhancing productivity. According to a recent report by McKinsey, companies that leverage data analytics in their operations can achieve productivity gains of up to 30%. This shift towards analytics allows manufacturers not only to streamline their processes but also to make informed decisions based on real-time data. As organizations harness the power of big data, they can identify inefficiencies, predict equipment failures, and optimize supply chain logistics, leading to significant enhancements in operational efficiency.

Moreover, a study by the International Data Corporation (IDC) highlights that manufacturers embracing data-driven technologies experience a 20% reduction in operational costs. With advanced analytics, businesses are equipped to analyze vast amounts of data from IoT devices and production lines, enabling them to make proactive adjustments to their operations. This capability not only boosts productivity but also fosters a culture of continuous improvement, helping organizations remain agile in the face of evolving market demands. By embedding analytics into their decision-making processes, manufacturers are poised to revolutionize their operations and unlock unprecedented levels of efficiency.

| Metric | Pre-Automation Value | Post-Automation Value | % Change |

|---|---|---|---|

| Production Output (units/day) | 1000 | 1300 | 30% |

| Downtime (hours/week) | 20 | 10 | -50% |

| Labor Cost ($/unit) | 25 | 18 | -28% |

| Defect Rate (%) | 5 | 3 | -40% |

| Energy Consumption (kWh/unit) | 12 | 9 | -25% |

In recent years, several industries have embraced process control and automation technologies, resulting in impressive productivity growth. A report from the International Federation of Robotics indicates that manufacturing automation can lead to productivity increases of around 30% across various sectors. For instance, automotive manufacturers implementing advanced robotics and automated assembly lines reported significant enhancements in efficiency, with production times reduced by 25% and labor costs cut by nearly 20%. This shift not only streamlines operations but also minimizes human error, leading to higher quality outputs.

Another notable example can be found in the food and beverage industry. According to a study by the Food Processing Suppliers Association, companies that adopted automation solutions improved their production throughput by up to 35%. These improvements stem from sophisticated process control systems that optimize ingredient handling and packaging processes, significantly reducing waste and downtime. As a result, firms can better meet consumer demand while increasing profitability, showcasing the profound impact that automation and process control have on contemporary manufacturing landscapes.

The manufacturing sector is at the brink of a technological revolution, with process control and automation paving the way for unprecedented efficiencies. As companies adopt advanced automation techniques, they are witnessing not only productivity gains but also a significant reduction in errors and operational costs. Future trends suggest that the next frontiers in manufacturing will focus on integrating AI and machine learning into existing systems. This will enable smarter decision-making and adaptive processes that can respond dynamically to changes in demand and supply.

Tip: Manufacturers should consider investing in cloud-based solutions that allow for real-time data analysis and monitoring. This can facilitate quick adjustments in the production line, minimizing downtime and maximizing output.

Moreover, sustainable automation is becoming a focal point, with new technologies being developed to enhance energy efficiency and minimize waste. The rise of collaborative robots—cobots that can work alongside human operators embodies this trend. As industries continue to explore these frontiers, those who embrace innovative control techniques will not only improve their productivity but also build a more sustainable and resilient manufacturing environment.

Tip: Implement pilot projects to test new technologies on a smaller scale before full-scale adoption. This can mitigate risks and allow for smoother integration into existing processes.