In the evolving landscape of automation machinery manufacturing, the need for optimization grows significantly. As we look toward 2026, businesses must adapt to rapid technological changes. It's crucial to align manufacturing processes with industry innovations. Companies face challenges in scaling operations while ensuring quality.

One major concern is the integration of advanced technologies. Many manufacturers struggle to harness the power of robotics and AI effectively. There is also the risk of overlooking employee training. Skilled workers are essential in this high-tech environment, yet many organizations hesitate to invest in their development.

Reflection is key. Are current practices truly effective? Are we reactive rather than proactive in addressing these challenges? Automation machinery manufacturing can thrive by embracing change. Success hinges not just on technology, but also on the people behind it. This holistic approach will pave the way for sustainable growth in the coming years.

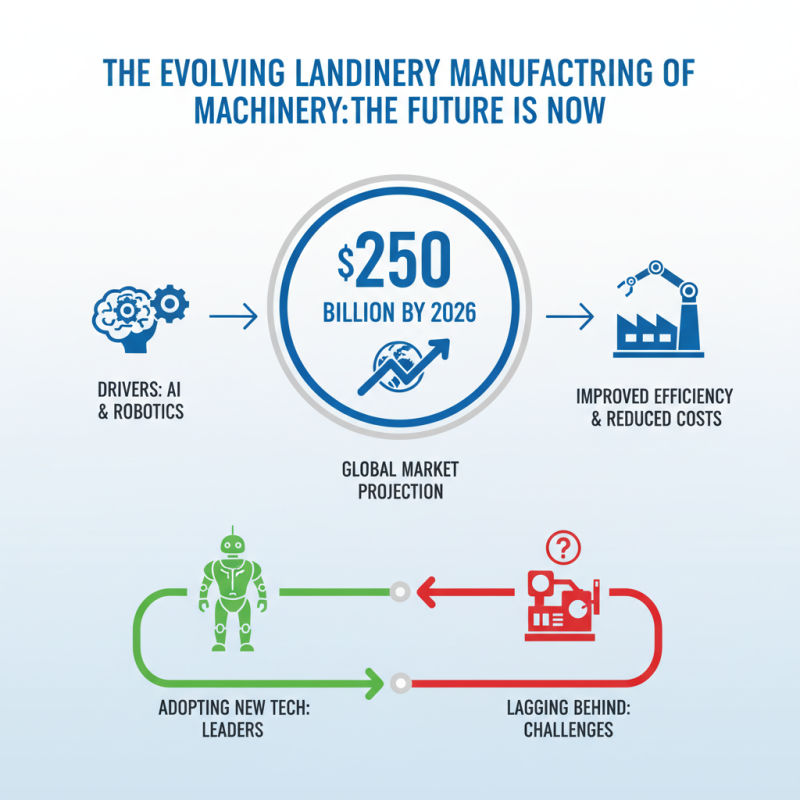

The landscape of automation machinery manufacturing is evolving rapidly. Recent reports indicate that the global market is projected to reach $250 billion by 2026. This growth is driven mainly by advancements in artificial intelligence and robotics. Companies are integrating these technologies to improve efficiency and reduce operational costs. However, not all manufacturers are keeping pace with these changes.

According to industry studies, 70% of successful manufacturers are implementing smart automation. This includes using data analytics to boost productivity. Yet, many small to mid-sized firms face challenges. They often resist change due to costs or lack of knowledge. Machine downtime remains a significant issue. Reports suggest that unplanned downtime can cost manufacturers up to $20,000 an hour.

Sustainability is another pressing trend. Increasingly, companies are focused on reducing their carbon footprint. Around 60% of manufacturers are investing in eco-friendly technologies. However, these initiatives often lead to higher initial costs. Balancing sustainability with profitability can be tricky. Manufacturers must navigate these complexities to stay relevant in the coming years.

Achieving growth in automation machinery manufacturing by 2026 hinges on leveraging key technologies that enhance operational efficiency. As per the latest market analysis, adopting advanced robotics can increase productivity by up to 30%. These robotic systems streamline repetitive tasks, allowing human workers to focus on complex problem-solving.

Incorporating Artificial Intelligence (AI) is crucial for optimizing manufacturing processes. AI can analyze vast amounts of data to predict equipment failures, significantly reducing downtime. Reports indicate that predictive maintenance using AI can decrease maintenance costs by 15-25%. Implementing smart sensors also enhances real-time monitoring, providing valuable insights into operational performance.

Tip: Regular training for the workforce is vital. Ensure your team is well-versed in new technologies and their applications. Enhancing skills will maximize the effectiveness of automation tools.

While these technologies offer great promise, challenges remain. Integration can be complex and costly. Moreover, many companies struggle to adapt their existing infrastructure to new systems. Continuous evaluation and a phased approach to implementation might mitigate these risks.

Tip: Start small. Identify one area for automation and assess its impact before scaling up. This allows for fine-tuning without overwhelming your resources.

As automation machinery manufacturing looks toward 2026, reducing costs and waste remains a crucial focus. A recent industry report indicates that manufacturing inefficiencies can account for up to 30% of total costs. Streamlining processes can markedly enhance profitability. Companies should consider investing in advanced technologies, such as smart sensors, to monitor production effectively and identify areas needing improvement.

Tip: Regularly assess your current machinery's performance. If it underperforms, it can waste materials. Switching to energy-efficient equipment can save on utility costs over time.

Another strategy is to implement lean manufacturing principles. This approach minimizes waste and enhances product quality. A study found that businesses adopting lean strategies saw up to a 20% reduction in waste. Staff training plays a critical role here. Continued education ensures employees understand best practices that foster a waste-reduction mindset.

Tip: Foster an environment where employees can suggest ideas. They often have insights that can lead to significant savings in both costs and materials.

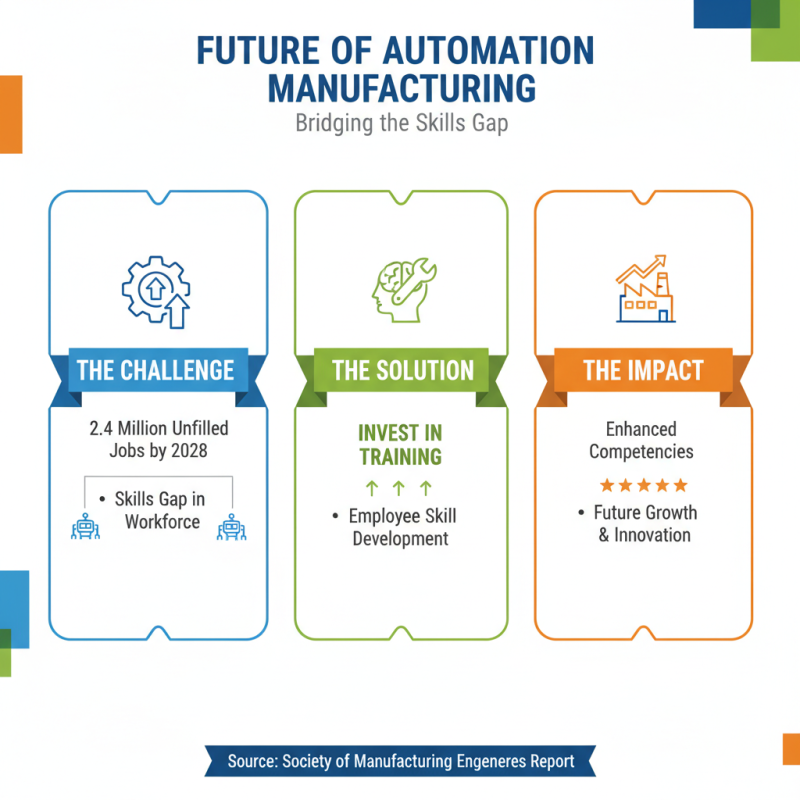

In the automation machinery manufacturing sector, workforce training is crucial for future growth. According to a report by the Society of Manufacturing Engineers, nearly 2.4 million jobs may be unfilled by 2028 due to skills gaps in the workforce. This situation signals a pressing need for companies to invest in employee skill development. Effective training programs can bridge this gap by equipping workers with relevant competencies.

The focus should be on hands-on training and modern skill sets. Automation technologies are evolving rapidly. Workers must adapt to new robotic systems and AI applications. A report by the Manufacturing Institute indicates that 80% of employers find new technologies challenging due to inadequate training. This clearly shows a disconnect between technological advancements and workforce preparedness. Companies need to reflect on their training methodologies and prioritize ongoing education.

Moreover, training should not just be a one-time event. Continuous learning is essential. On-the-job training, workshops, and online courses can provide the necessary resources. The International Federation of Robotics notes that over 400,000 industrial robots are expected to be installed annually by 2025. Without a skilled workforce, these advancements may lead to inefficiencies. A proactive approach in training will ensure that manufacturers remain competitive in the global market.

The automation machinery manufacturing sector is poised for significant growth by 2026. Market projections indicate a surge in demand driven by advancements in artificial intelligence and robotics. Companies must adapt to these changes. Embracing new technologies can enhance efficiency and reduce costs.

Growth opportunities lie in niche markets. Customization is key. Tailored solutions can meet specific industry needs. Investing in research and development is crucial. It can lead to innovative products that stand out. However, challenges remain. Many firms struggle to keep pace with rapid technological advancements. Some may overlook the importance of skilled labor in this transition.

Analyzing market trends will be vital. Understanding customer preferences can guide product development. Furthermore, embracing sustainable practices may attract a more conscious consumer base. Automation is not just about machines; it's about rethinking business models. Companies need to reflect on their strategies regularly. Balancing growth with responsible practices is essential for long-term success.