Manufacturing control systems are vital for modern production processes. They streamline operations and enhance efficiency. These systems manage the flow of materials and monitor equipment performance.

In a competitive market, staying ahead is crucial. Manufacturing control systems help companies achieve this goal. They allow real-time data analysis, leading to informed decision-making. However, not every system works perfectly. Some may face integration challenges or lack user-friendly features. These issues can hinder productivity.

Implementing manufacturing control systems requires careful planning. Companies must customize systems to fit their unique needs. This can involve ongoing training and adjustments. While these systems offer benefits, they also demand constant evaluation to maximize their effectiveness.

Manufacturing control systems play a crucial role in modern production environments. These systems help manage and optimize processes. They ensure effective communication between machines, operators, and management. This integration allows real-time monitoring and decision-making.

In today's factories, automation is essential. Sensors and software collect data on performance. This data drives improvements in efficiency and quality. However, not all systems are perfect. Sometimes the data collected can be inaccurate. Operators may overlook machine malfunctions, leading to delays.

Decision-making relies heavily on these systems. Yet, human input remains vital. A skilled worker's intuition can catch what machines might miss. Balancing technology and human oversight is key. Some companies struggle with this balance. They may trust the system too much, ignoring valuable insights from their team. Manufacturing control systems provide enormous benefits, but they aren’t infallible.

Manufacturing control systems play a crucial role in modern production environments. They integrate various components and technologies to streamline operations. At the heart of these systems are sensors. These devices collect real-time data from machinery and processes. They help identify issues early, allowing for quick adjustments.

Another key component is the control software. This software analyzes data and optimizes workflows. It communicates with machines, coordinating tasks effectively. However, not every system operates flawlessly. Connectivity issues may arise, disrupting production. Sometimes, operators feel overwhelmed by data overload. Balancing information is critical for effective decision-making.

Lastly, human operators remain essential. Despite technological advancements, human judgment is irreplaceable. Operators need training to interpret data accurately. Misunderstandings can lead to mistakes. Regular reflections on system performance can highlight areas for improvement. Technological integration should enhance, not complicate, manufacturing processes. This balance is vital for successful production.

| Component | Functionality | Technology | Benefits |

|---|---|---|---|

| Manufacturing Execution System (MES) | Tracks and monitors production processes in real-time. | Software Application | Improves efficiency and reduces production costs. |

| Distributed Control System (DCS) | Controls complex processes and systems across a facility. | Networked Control System | Enhances process visibility and control. |

| Supervisory Control and Data Acquisition (SCADA) | Monitors and controls industrial processes remotely. | Software and Hardware Interface | Real-time monitoring and improved safety. |

| Enterprise Resource Planning (ERP) | Integrates all facets of an operation, including planning, manufacturing, and sales. | Integrated Software System | Streamlines business processes and data management. |

| Programmable Logic Controller (PLC) | Controls machinery and factory assembly lines. | Industrial Computer | Increases automation and precision in manufacturing processes. |

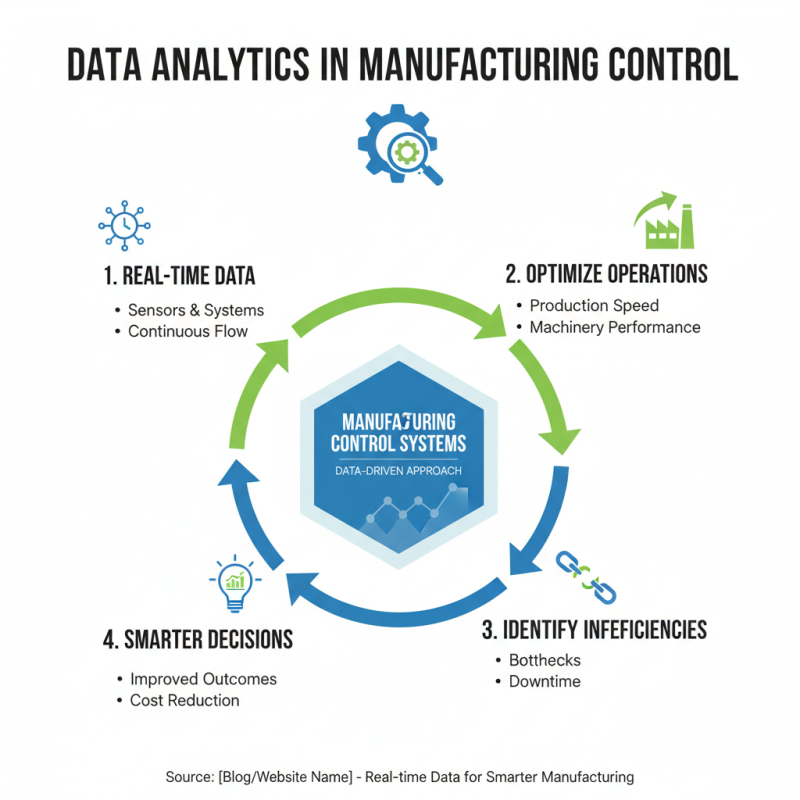

Data analytics has become a crucial component of manufacturing control systems. These systems rely on real-time data to optimize operations. By analyzing metrics like production speed and machinery performance, manufacturers can identify inefficiencies. This data-driven approach leads to smarter decision-making and improved outcomes.

For instance, a factory may notice that a particular machine frequently breaks down. Data analytics can reveal patterns in its operational history. This insight prompts maintenance teams to address the root cause. Consequently, unplanned downtimes decrease, and productivity increases.

However, integrating data analytics is not always straightforward. Some facilities struggle with outdated systems. They may find it challenging to collect accurate data. Additionally, staff may require training to understand complex data reports. Without addressing these issues, the potential of analytics remains unrealized. Manufacturers should reflect on their current practices. Can they enhance their data collection methods or invest in better training? Making such changes can lead to significant improvements.

Manufacturing control systems play a crucial role in determining production quality and controlling costs. These systems streamline operations by monitoring and managing production processes in real-time. They collect data about various metrics like machine performance, employee efficiency, and material usage. This data helps identify inefficiencies quickly, which can lead to significant cost savings.

One example illustrates this well. A factory with a manufacturing control system can pinpoint a machine that frequently breaks down. Such insights allow for proactive maintenance. Waiting until equipment fails could result in costly downtimes. However, this doesn't guarantee perfection. Sometimes, data can be misinterpreted, leading to misguided decisions.

**Tips:** Regularly review your data collection methods. Inaccurate data can skew results. Train your team to analyze data critically. Also, consider how changes impact all stages of production. Small adjustments can sometimes yield unexpected costs. A holistic view often brings better solutions.

The future of manufacturing control systems is evolving rapidly. Advances in technology are transforming how industries operate. Integration of IoT and AI is becoming common. Manufacturers are increasingly adopting smart systems that can predict maintenance needs. This reduces downtime and enhances efficiency.

Many companies struggle with implementation. Legacy systems often hinder progress. Embracing change can be challenging. Training staff on new technologies is crucial. Often, there is resistance to new methods. A proactive approach is essential to overcome these barriers.

Tips for success include starting small. Test new systems in limited areas first. Monitor results carefully before wider adoption. Engage your team during transitions. Their insights might unveil critical improvements. Keep communication open to foster a collaborative atmosphere. The shift to advanced manufacturing control systems holds great potential. Embrace it cautiously, and learn along the way.