In today's rapidly evolving business landscape, the adoption of automation electric controls is becoming increasingly essential. According to a report by McKinsey, companies can enhance productivity by up to 20% through automation technologies. Failing to implement these systems could lead to falling behind competitors. For instance, manufacturers adopting automation report a 30% reduction in operational costs.

However, the journey towards effective integration is not always smooth. Many businesses struggle with selecting the right technology and training staff effectively. A survey from PwC indicates that 40% of firms cite a lack of skilled workers as a barrier to automation. Companies often overlook the importance of a comprehensive strategy in favor of quick fixes, resulting in limited results.

Exploring automation electric controls requires a mindset shift. Organizations must not only invest in technology but also rethink workflows. Engaging employees is crucial, as their feedback can shape the automation process. Yet, many overlook this step, leading to resistance and inefficiencies. Addressing these challenges head-on can pave the way for successful implementation, ultimately unlocking significant value.

Automation electric controls are vital in modern business. They increase efficiency and reduce manual effort. By implementing these systems, companies can streamline operations. This technology often leads to significant cost savings.

Tips: Start with a small project. Test the system before a full rollout. Gradually expand it as you learn more.

Understanding the benefits is key. These systems allow real-time monitoring of operations. Data can help in decision-making. However, not every business is ready for this change. Consider your current processes and workforce readiness.

Tips: Train your staff early. Ensure they understand how to use new systems. Feedback loops can enhance the overall implementation process. Keep lines of communication open for improvements.

Assessing your business needs is a crucial first step in implementing automation electric controls. According to a report by McKinsey, organizations that adopt automation can boost productivity by 20-30%. However, not all businesses are ready for this transition. Understanding your specific needs is vital.

Identify tasks that are repetitive and time-consuming. These are prime candidates for automation. For instance, if your team spends hours on manual data entry, integrating electric controls can streamline this process significantly. However, consider the initial investment. Automation systems can be expensive. Analyze whether the long-term savings justify the upfront costs.

Tips: Focus on scalability. Choose automation solutions that grow with your business. Also, ensure staff are trained. A well-informed team can maximize the effectiveness of any new system. Evaluate progress regularly. Gather feedback from employees to identify areas needing adjustment. Embrace a culture of continuous improvement. This mindset can make a big difference in successful automation adoption.

Choosing the right technology is key for automation success. Analyze your specific needs before diving in. Consider the scalability of the equipment. Can it grow with your business? Also, assess compatibility with existing systems. Mismatched technology can lead to issues and unforeseen costs.

Focus on user-friendliness and reliability. Equipment that is hard to use can slow down workflows. Look for solutions that integrate with your team's skills. You might need training. Are you prepared for that? Pay attention to feedback from your staff. They often know what works and what doesn’t.

Don't forget about support and maintenance. A great machine needs proper care. Understand the service requirements beforehand. Neglect can lead to breakdowns and delays. Evaluate all factors carefully. The right choice enhances efficiency, but mistakes can be expensive.

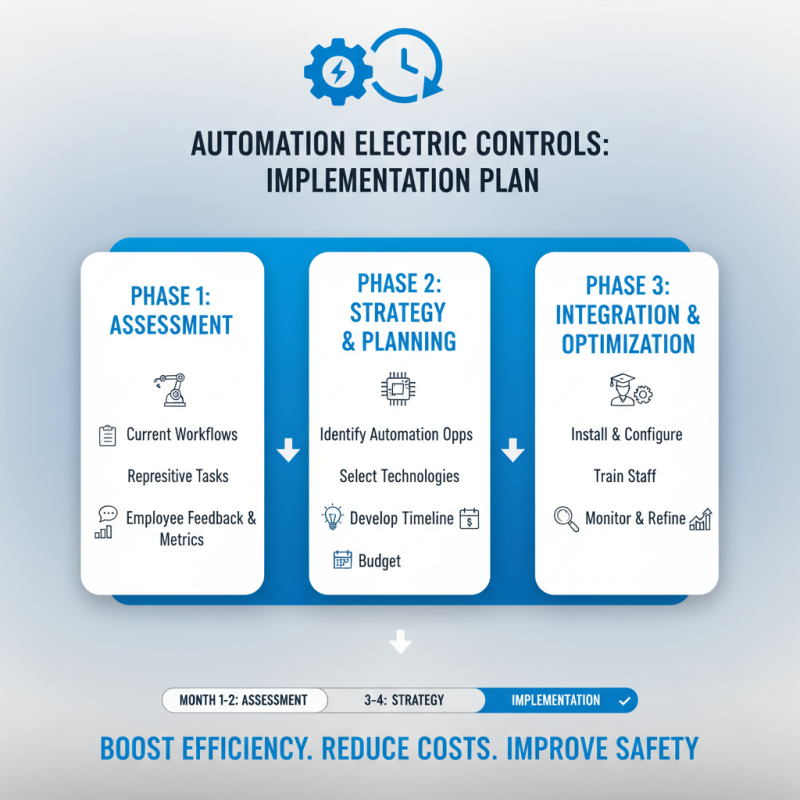

Developing an effective implementation plan and timeline is crucial when integrating automation electric controls. Begin by assessing your current workflows. Identify repetitive tasks that could benefit from automation. Evaluate employee feedback and performance metrics. This data will highlight areas for improvement and guide your strategy.

Next, establish clear milestones. Set achievable goals that motivate your team. For instance, outline the phases of implementation—design, testing, and deployment. Assign responsibilities to ensure accountability. Engage your staff in the process. Their insights can shape better solutions. Keep in mind that challenges will arise. You might face equipment compatibility issues or resistance to change. Reflect on these obstacles and adapt your plan accordingly.

Finally, monitor progress closely. Use analytics to measure success and identify problems early. A flexible timeline allows you to make necessary adjustments. Celebrate small wins to keep morale high. However, be prepared to revisit your strategies. Continuous improvement is vital as automation technology evolves.

Training employees is crucial when implementing automation electric controls. Skilled workers can utilize technology effectively. Regular workshops help in understanding new systems. Hands-on training is vital for confidence. Employees should feel comfortable with the tools they use daily.

Maintenance is another key component. Regular checks prevent unexpected failures. A maintenance schedule keeps everything running smoothly. However, some may overlook small issues until they escalate. It’s essential to encourage a culture of reporting problems. Neglecting minor concerns can lead to bigger headaches down the line.

Encouraging feedback from employees enhances the automation process. Listening to their experiences helps identify weak spots. Continuous improvement is necessary. If an employee struggles, the system might need adjustments. Automation should evolve with the workforce's needs, not against them.

| Department | Employee Training Completed | Maintenance Schedule (Frequency) | Last Maintenance Date | Next Maintenance Due |

|---|---|---|---|---|

| Production | Yes | Monthly | 2023-09-01 | 2023-10-01 |

| Quality Control | No | Quarterly | 2023-06-15 | 2023-09-15 |

| Maintenance | Yes | Weekly | 2023-09-25 | 2023-10-02 |

| IT Department | Yes | Annually | 2023-01-10 | 2024-01-10 |

| Logistics | No | Bi-Monthly | 2023-08-05 | 2023-10-05 |