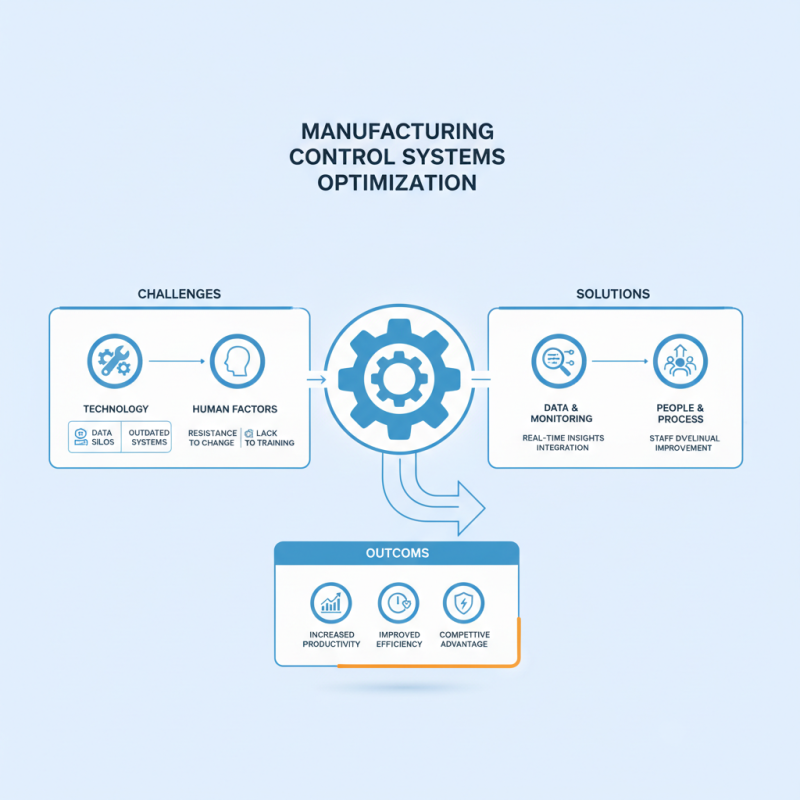

Manufacturing control systems play a vital role in enhancing operational efficiency in today’s production environment. According to a recent report by McKinsey, companies implementing advanced manufacturing control systems can increase productivity by up to 20%. This statistic underlines the importance of optimizing these systems to stay competitive. However, many manufacturers struggle to fully leverage their potential.

Challenges often arise not only from technology but also from human factors. A survey by Gartner indicates that about 70% of companies face difficulties in adopting new manufacturing technologies. Thus, it's essential to reassess existing processes and systems regularly. Some organizations may overlook the significance of staff training and development, which directly impacts system performance.

Manufacturers must focus on specific areas like data integration and real-time monitoring. These elements are crucial for making informed decisions quickly. It's easy to assume that traditional methods are enough, yet evolving market demands call for a more agile approach. By embracing continual improvement and making adjustments based on real data, manufacturers can truly optimize their control systems for better outcomes.

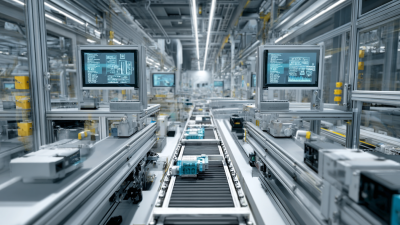

Manufacturing control systems play a critical role in optimizing production processes. They integrate various functions, including planning, scheduling, and inventory management. A comprehensive understanding of these systems can significantly impact efficiency. According to a recent industry report, manufacturing companies that optimize their control systems can see productivity increases of up to 30%. However, many still struggle with implementation and effective use.

One essential tip is to ensure clear communication across departments. Miscommunication can lead to delays and errors. Establish standardized protocols to facilitate better coordination. Another important aspect is to leverage data analytics. It can provide insights into production bottlenecks. The use of real-time data allows managers to make informed decisions promptly.

Investing in training is also crucial. Employees should understand how to use the control systems fully. A lack of knowledge can hinder optimization efforts. Implement feedback loops to identify areas needing improvement. This fosters a culture of continuous growth and learning within your team. Remember, perfection is not achievable; acknowledging flaws is essential for progress in manufacturing control systems.

Identifying key performance metrics is crucial for optimizing manufacturing control systems. These metrics provide insights into efficiency, quality, and productivity. Manufacturing leaders often struggle to define what truly matters. Without clarity, optimization efforts may yield minimal results.

Common metrics include overall equipment effectiveness (OEE), first-pass yield, and cycle time. OEE measures how effectively a machine is utilized. It considers availability, performance, and quality. First-pass yield assesses the percentage of products meeting specifications on the first attempt. Cycle time tracks how long it takes to produce one unit. These metrics reveal hidden inefficiencies.

It’s important to note that not all metrics are relevant for every facility. Some companies chase metrics without understanding their implications. This can lead to confusion and wasted resources. Reflecting on the selected metrics is necessary. Regular reviews can highlight gaps and inconsistencies. Smart decision-making hinges on choosing the right metrics for your unique manufacturing context.

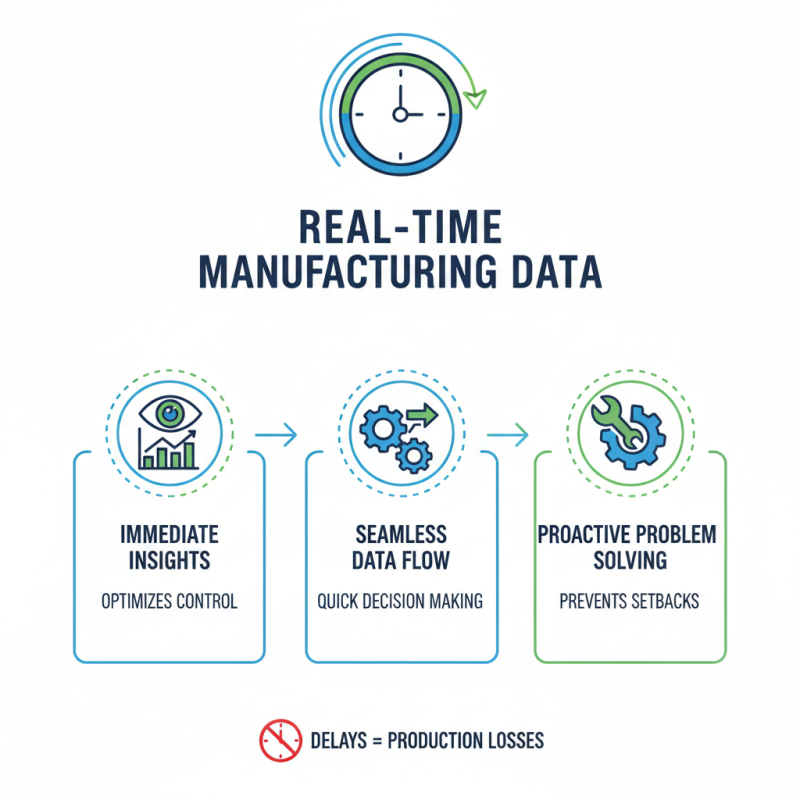

Real-time data monitoring is crucial for optimizing manufacturing control systems. It offers immediate insights that drive better decisions. When data flows seamlessly, you can react quickly to issues. Delays in information can lead to production setbacks.

One essential tip is to integrate sensors throughout your production line. These sensors can track performance and detect anomalies. Regularly reviewing this data helps identify patterns. It's not always perfect. Sometimes, sensors might fail or provide inaccurate readings. This requires ongoing adjustments and evaluations.

Another important aspect is to use analytics tools to interpret the data. Raw data alone can be overwhelming. Visualizing this data can uncover hidden opportunities for efficiency. However, analytics tools are not infallible. They often need calibration and adjustments to remain effective. Keep an ongoing dialogue with your team about the insights gathered. Collaborative decision-making enhances the effectiveness of the data-driven approach.

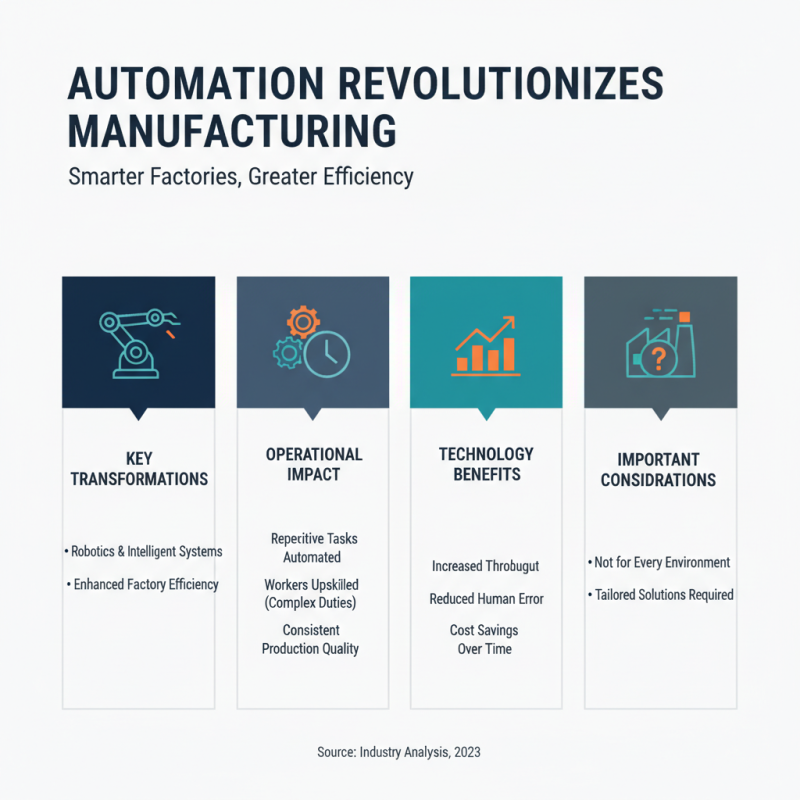

Automation technologies have transformed manufacturing processes significantly in recent years. With the rise of robotics and intelligent systems, factories can operate more efficiently. Automated systems can handle repetitive tasks, which frees up workers for more complex duties. These technologies help in maintaining consistency across production lines. However, not all automation solutions are suitable for every manufacturing environment.

Incorporating automation requires careful planning. Many companies rush into adopting the latest tech, only to face integration issues. It is essential to assess current workflows first. Understanding where automation will have the biggest impact can save time and money. Additionally, employee training is crucial. A workforce that is well-versed in automation tools can better adapt to changes. Neglecting this aspect can lead to frustration and reduced productivity.

Monitoring and adjusting automation systems is another area often overlooked. Regular reviews help identify inefficiencies. Sometimes, automated systems can create bottlenecks if not properly calibrated. The goal is to streamline, not complicate, operations. Balancing technology and human oversight is key. Being aware of these challenges can lead to a more successful implementation of automation in manufacturing.

Manufacturing control systems are essential for streamlining operations and boosting productivity. However, continuous improvement is crucial. In fact, organizations that implement regular feedback loops see a 20% increase in operational efficiency, per a recent industry report. Making small, incremental changes can lead to significant long-term gains.

Tip: Regularly assess your system's performance. Identify bottlenecks and areas of waste. Employ strategies like Lean manufacturing to eliminate inefficiencies. This can help save costs and improve overall output.

Another tip involves training employees. Engaged staff understand their roles better. They can identify issues more quickly. A study by the Manufacturing Institute indicates that properly trained workers can enhance productivity by up to 15%. Yet, finding the right training methods can be challenging. It requires ongoing evaluation and adaptation.

Engaging in continuous monitoring ensures you remain agile. Make data-driven decisions based on real-time insights. Yet, align these insights with your long-term goals. Balancing immediate needs with future aspirations is often difficult but necessary for sustainable growth.

| Tip Number | Tip Description | Expected Outcome | Frequency of Review |

|---|---|---|---|

| 1 | Implement Real-Time Data Monitoring | Enhanced decision-making capabilities | Daily |

| 2 | Utilize Predictive Analytics | Reduced downtime and maintenance cost | Monthly |

| 3 | Standardize Processes | Increased efficiency and quality | Quarterly |

| 4 | Regular Training for Staff | Improved operational performance | Bi-Annual |

| 5 | Set Performance Benchmarks | Clear accountability and focus | Annually |

| 6 | Integrate Systems for Data Flow | Streamlined operations and reporting | Ongoing |

| 7 | Conduct Regular Audits | Identify areas for improvement | Semi-Annual |

| 8 | Encourage Employee Feedback | Enhanced morale and innovation | Continuous |

| 9 | Adopt Lean Manufacturing Principles | Waste reduction and process efficiency | Ongoing |

| 10 | Leverage Advanced Technologies | Enhanced competitive advantage | Annual Review |