The landscape of manufacturing is evolving rapidly, driven by controls and automation technologies. According to a recent report by McKinsey, industries that adopt these technologies see productivity increases of up to 30%. This shift is not just about efficiency; it’s about redefining the workforce. As automation takes over repetitive tasks, skilled workers are needed for more complex roles.

Yet, the integration of controls and automation presents challenges. A survey by PwC revealed that 59% of executives express concern over job displacement. The human element remains essential, and organizations must navigate this transition carefully.

Investments in smart manufacturing are expected to reach $300 billion by 2025, highlighting the urgency for businesses to adapt. Companies that fail to embrace these trends risk obsolescence. While the outlook is promising, reflection on workforce impacts and ethical considerations is crucial. Balancing technological advancement with human value will be key to sustainable growth.

Emerging technologies are reshaping industrial automation and control systems as we know them. Companies are increasingly embracing the Internet of Things (IoT) for connectivity. Smart sensors now gather real-time data, enabling better decision-making. Yet, the integration of IoT raises security concerns. Cybersecurity must evolve alongside these advancements.

Artificial Intelligence (AI) is becoming a cornerstone in automation. Predictive maintenance powered by AI helps to foresee equipment failures. However, reliance on AI can lead to overconfidence. Human oversight remains crucial in managing complex systems. The balance between automation and human intuition proves challenging.

Edge computing is also on the rise. By processing data closer to the source, latency decreases significantly. This shift enhances operational efficiency but challenges traditional data management approaches. It prompts reflection on how industry adapts to this decentralized model. Businesses must navigate these changes thoughtfully.

The integration of AI and machine learning into manufacturing processes is transforming industry dynamics. Companies are now leveraging these technologies to enhance efficiency and precision. Automation systems equipped with AI can analyze vast amounts of data quickly. This leads to better decision-making in real time. For instance, smart sensors can monitor equipment performance and predict maintenance needs.

However, the transition is not without challenges. Many organizations struggle with data quality and integration. Machine learning algorithms require quality data for accurate predictions. Inconsistent data can lead to flawed outcomes. Additionally, there is a significant skills gap in the workforce. Employees may require extensive training to adapt to these new technologies.

Productivity gains are promising, yet they come with uncertainties. Companies might invest heavily in AI and still not see immediate benefits. The landscape is evolving, and not every implementation will succeed. Experimentation is crucial. The industry must learn from both successes and failures. Embracing a culture of continuous improvement might ease the path forward.

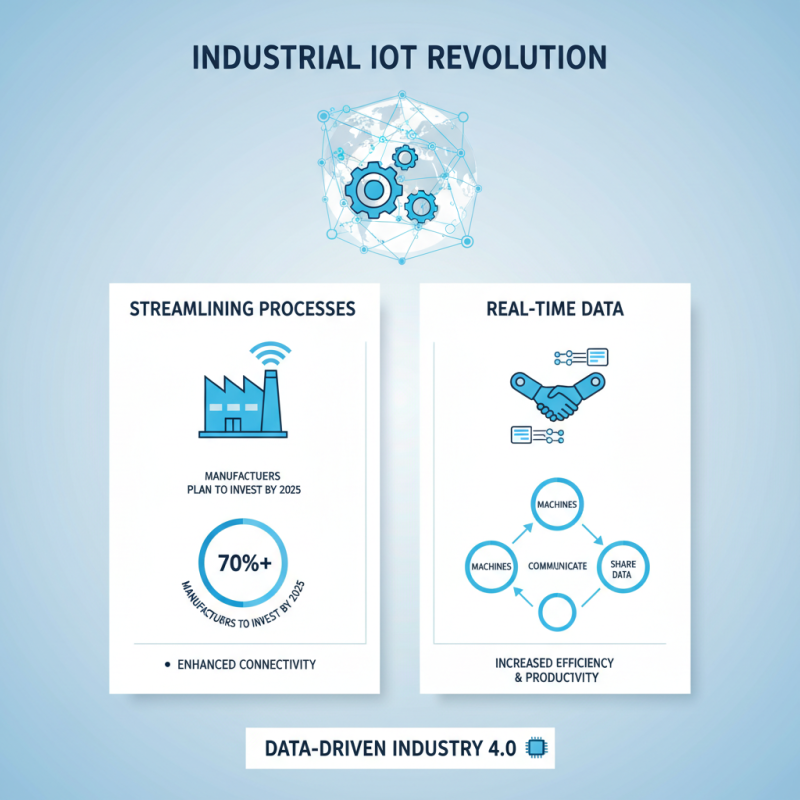

The Internet of Things (IoT) is revolutionizing industrial efficiency. Companies are increasingly adopting IoT technologies to streamline processes. According to a recent industry report, over 70% of manufacturers plan to invest in IoT solutions by 2025. This technology enhances connectivity, allowing machines to communicate and share data in real-time.

IoT devices collect a vast amount of data. This data helps in predictive maintenance, reducing downtime significantly. In fact, some studies suggest that IoT can cut maintenance costs by 30-50%. However, many organizations still struggle with data integration. With so many devices and platforms, establishing a unified system can be challenging.

Tip: Invest in a robust data management platform. A good platform will integrate various IoT devices and the data they generate.

IoT also enables better supply chain visibility, leading to more informed decisions. Fleet tracking, for instance, can optimize delivery routes. Yet, not all companies benefit equally. Smaller businesses may lack the resources to implement these technologies effectively.

Tip: Start small. Adopt one IoT solution that addresses a specific challenge in your operations. This gradual approach can yield quicker wins and lay the groundwork for larger innovations.

As IoT continues to evolve, industries must adapt. Embracing these technologies can create significant competitive advantages. But, organizations should also be mindful of the inherent challenges that come with rapid technological changes.

In recent years, safety and security in industrial automation have become critical focus areas. A report by the International Society of Automation indicates that nearly 60% of manufacturers experienced security breaches in the past year. This alarming trend underscores the importance of robust security frameworks. The rise of IoT devices has expanded attack surfaces, making vigilance essential.

Implementing cybersecurity measures starts with employee training. Regular sessions ensure that your workforce is aware of potential threats. It's easy to overlook simple things, like using strong passwords. Workers must understand that small lapses can lead to significant vulnerabilities. Also, regular audits of systems can reveal hidden risks.

On the safety front, integrating advanced technologies like AI and machine learning can enhance operational safety. These technologies can monitor equipment for anomalies. However, reliance on automation can be a double-edged sword. If systems malfunction, human operators must still be equipped to react swiftly. A study by Gartner suggests that 70% of industrial accidents could be avoided with proper training and technology integration. Addressing these issues thoughtfully can lead to a safer industrial environment.

Sustainability is reshaping the industrial landscape. Companies are pushing for greener operations and seeking innovative automation solutions. This drive not only reduces environmental impact but also提升效率. Automation is key in optimizing resources and minimizing waste. Smart technologies can monitor energy consumption in real time. They help in adjusting processes to fit sustainability goals.

Integrating renewable energy sources is crucial. Industries can utilize solar or wind energy more effectively. This shift requires specific automation tools to manage energy flow. Smart grids play a significant role here. They facilitate energy distribution and ensure reliability while supporting green initiatives. Companies must invest in training for their workforce, teaching them to adapt to new technologies supporting sustainability.

Tip: Regularly assess your energy consumption. Small adjustments can lead to significant changes. Encourage your team to suggest improvements. Involve everyone in the sustainability journey; it creates ownership. Also, be open to trial and error. Not every innovation will succeed. Learning from mistakes can shape better practices for the future.