In the rapidly evolving world of technology, automation and controls play a vital role. Businesses seek enhanced efficiency and lower operational costs. This quest drives innovation in automation and controls solutions across industries.

The 2026 landscape presents groundbreaking tools and systems. Each solution offers unique features designed to streamline processes. However, the path to adopting automation isn't always smooth. Many organizations hesitate due to potential risks and implementation complexities.

Investing in automation and controls means addressing both opportunities and challenges. Companies must consider their specific needs and readiness. The right approach can lead to remarkable improvements. A tailored strategy will foster success, but it requires careful analysis and commitment.

As we approach 2026, automation technologies continue to reshape manufacturing. These advancements promise to enhance efficiency in significant ways. Manufacturers are exploring more flexible automation solutions. Robots designed for collaborative work are a key focus. They can adapt to changing tasks while maintaining precision. This shift points toward a more responsive manufacturing ecosystem.

The rise of artificial intelligence is shaping automation trends. Intelligent systems analyze data and predict maintenance needs. This can reduce downtime, yet it raises questions about reliability. How much can we trust these systems? Human oversight is still critical. As machines take on more responsibilities, workers must adapt to new roles. Training programs need to evolve quickly.

Another trend involves the integration of IoT devices. These smart tools provide real-time data insights. However, cybersecurity remains a concern. Protecting sensitive information is essential for any automation strategy. Companies must be vigilant. Embracing automation is not without its challenges. Continuous reevaluation of strategies is necessary. The balance between technology and human skill will define future success.

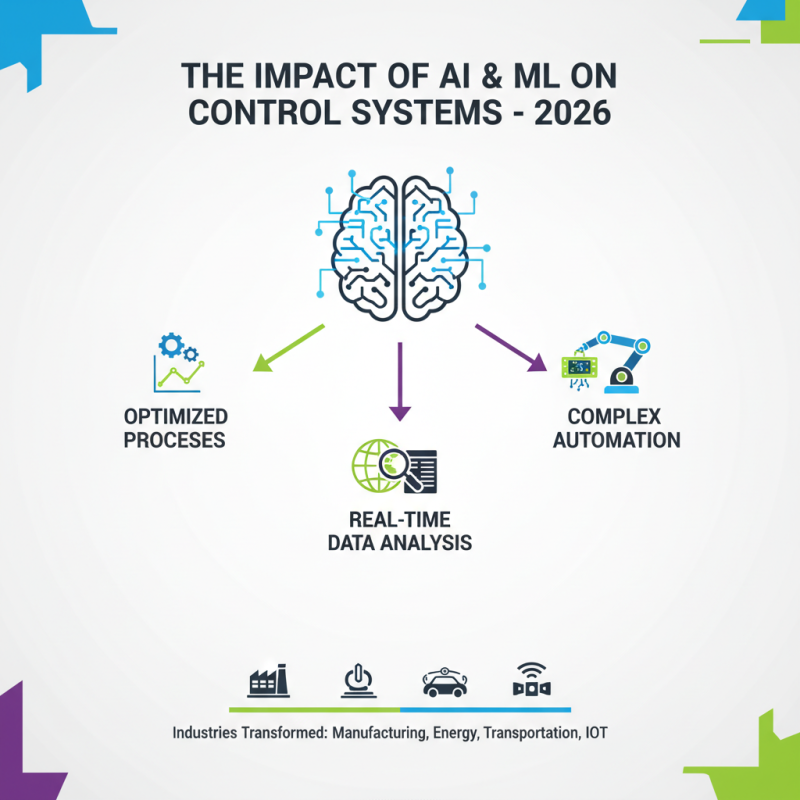

The impact of artificial intelligence and machine learning on control systems in 2026 is significant. These technologies are reshaping automation across various industries. AI algorithms analyze vast data sets in real-time. They optimize processes that were once too complex for traditional control methods.

Machine learning models can identify patterns within operations. This allows for predictive maintenance, reducing downtime. However, the reliance on algorithms raises concerns. What happens if the data fed into the system is flawed? Errors can propagate quickly, and the consequences may be severe.

Stakeholders must balance innovation with caution. AI-driven control systems can enhance efficiency, but they must be monitored. Continuous feedback loops should be integrated. This ensures adaptability and reduces risks associated with faulty predictions. As we embrace these advancements, reflection on potential pitfalls is essential. We must remain vigilant and prioritize ethical considerations.

In evaluating automation solutions for industrial settings, it's crucial to focus on key metrics that drive efficiency. A recent report found that 70% of companies aim to reduce operational costs through automation. Operating time is a vital metric; systems that operate 24/7 can minimize downtime. This can lead to a 30% increase in productivity.

Another significant metric is return on investment (ROI). Many automation projects can yield an ROI of 15% to 25% within the first year. However, not all projects meet this goal, raising questions about selection processes. Complexity can be a barrier. A 2023 survey indicated that 40% of companies struggled with software integration.

Energy efficiency is equally important. Research highlights that automation can reduce energy consumption by up to 20%. Yet, companies sometimes overlook maintenance needs, which can erode these gains. Regular assessments and updates are necessary to sustain efficiency levels. Failure to implement these checks can lead to unexpected costs down the line.

In today's fast-paced industrial landscape, automation tools and software play a crucial role in enhancing operational performance. According to a recent report by McKinsey, automation can reduce operational costs by up to 30%. This statistic drives organizations to invest more in innovative solutions. Effective automation minimizes manual tasks, allowing teams to focus on strategic projects.

The implementation of these tools can, however, be challenging. A survey by Gartner indicates that nearly 80% of automation projects fail to meet expectations. Organizations often overlook the importance of employee training. Without adequate training, employees struggle to adapt to new systems. This gap in preparation can lead to inefficiencies, counteracting the potential gains from automation.

Integrating advanced software can improve response times and data accuracy. TechRepublic reported that organizations that leverage automation see a 50% increase in productivity. But, reliance on technology comes with risks. Systems can malfunction, leading to temporary downtime. Continuous monitoring is essential to ensure that automated processes run smoothly. As the industry evolves, balancing automation with human oversight will be crucial.

Advanced automation solutions are driving efficiency gains across various industries. According to a recent industry report, implementing automation technologies can boost productivity by up to 40%. One notable case involves a manufacturing facility that reduced its operational costs by 30% after adopting automated systems. The shift led to quicker production cycles and minimized human error, but initial challenges arose during the training phase.

In the logistics sector, automation has revolutionized supply chain management. A study revealed that companies using advanced automation tools improved delivery speed by 25%. However, integrating these solutions often presents obstacles. For instance, a major warehouse faced difficulties in synchronizing existing processes with new technologies. Despite these challenges, the outcomes were positive, showcasing that strategic investments in automation yield substantial returns.

Automation also enhances data collection. Real-time analytics offer deeper insights into operational inefficiencies. A manufacturing plant that utilized these analytics saw a 20% decrease in downtime. Yet, relying heavily on automation raises concerns about cybersecurity. Organizations must remain vigilant and address potential vulnerabilities in their systems, ensuring that advancements do not come at the expense of security.

This chart illustrates the efficiency gains achieved by various automation solutions in real-world applications. The data represents the percentage increase in operational efficiency after implementing advanced automation technologies across different industries.