In today's fast-paced industrial landscape, manufacturing process automation is a game-changer. According to Dr. Emily Chen, a renowned expert in automation technology, "Efficiency is the heart of manufacturing." This underscores the critical role automation plays in improving production efficiency.

Manufacturers face numerous challenges. They seek to reduce costs while maintaining quality. Manufacturing process automation can address these demands effectively. It streamlines operations, minimizes errors, and enhances output quality. However, the transition to automated processes is not without its hurdles. Companies must address employees' concerns and invest in training.

Despite the clear advantages, not all organizations embrace manufacturing process automation wholeheartedly. Some fear job losses and a steep learning curve. It's crucial to balance technology with human input to maximize productivity. Thus, understanding automation's potential is vital while acknowledging its impact on the workforce.

Manufacturing process automation is transforming industries. This technology enhances productivity and efficiency. It allows for quicker production rates, which can lead to higher profits. When businesses automate their processes, they often reduce human error. This increases the quality of the final product. However, not all companies are reaping these benefits yet.

One of the key tips is to evaluate workflow before implementing automation. Identify bottlenecks in the process. This could be tedious, but it pays off. Consider involving employees in the discussion. Their insights can lead to better solutions. Another practical tip is to start small. Choose one process to automate. This allows for adjustments without overwhelming the entire operation.

Investing in training is crucial. Employees need to understand the new systems. Regular workshops can help ease the transition. Companies should also be open to feedback. This helps refine processes over time. Remember, automation can introduce new challenges. Embracing change is necessary for continuous improvement.

In today’s competitive landscape, businesses are turning to automation to enhance efficiency. Automation streamlines the manufacturing process, reducing manual tasks. This leads to faster production cycles. Machines can work tirelessly, completing tasks with precision. Human errors are minimized in repetitious jobs, freeing workers for more strategic roles.

Implementing automation, however, isn’t always smooth. Companies may face challenges during integration. Employees might resist changes, fearing job loss. Proper training is crucial. Companies must ensure workers adapt to new technologies. Regular feedback on automation's effectiveness helps fine-tune processes. Evaluating outcomes can lead to further improvements.

While automation boosts efficiency, it’s important to consider the overall impact. Not all tasks can be automated successfully. Balancing automation with human involvement often yields the best results. Every business needs to assess what works and what doesn't. A thoughtful approach to automation can significantly enhance productivity.

Manufacturing process automation offers significant advantages in cost reduction and resource optimization. A recent industry report indicated that businesses implementing automation can reduce operational costs by up to 30%. This reduction is largely due to decreased labor expenses and increased efficiency. Machines operate with precision and speed, minimizing waste and resource use in production.

Moreover, automation enables better resource management. For instance, a study by the Global Automation Association found that companies using automated systems improve resource allocation by 25%. This leads to more sustainable production practices. Yet, not all businesses embrace this change easily.

Resistance to new technologies can hinder progress. Some employees may feel threatened by automation and need proper training to adapt.

Additionally, while automation can streamline processes, it brings challenges. Initial implementation costs can be high. Companies must balance between upfront investments and long-term savings. Businesses should conduct thorough analyses before diving in.

This careful planning can prevent misallocation of resources. Ultimately, the goal is to transform operations while maintaining a human touch in the workplace.

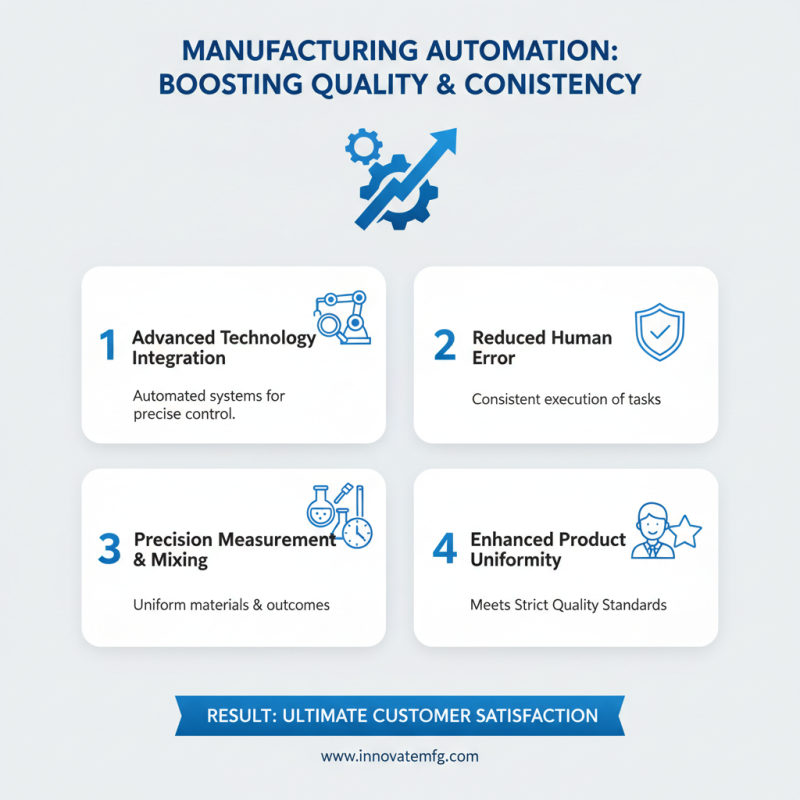

Manufacturing process automation significantly enhances product quality and consistency. By integrating advanced technology, businesses can ensure that every unit produced meets strict quality standards. Automated systems reduce human error, which is often a source of variability. For example, a machine can consistently measure and mix materials with precision, leading to uniform outcomes. This consistency is vital for maintaining customer satisfaction.

However, automation isn’t without its challenges. Implementing new technologies can lead to resistance among workers who may fear job loss. It's crucial to address these concerns and provide adequate training. If not handled well, this can affect morale and lead to errors. Additionally, automated processes require regular maintenance and updates. Neglecting these can result in decreased efficiency and product quality over time.

Moreover, the initial cost of automation can be high. Businesses must weigh the long-term benefits against the upfront investment. Sometimes, a partial automation approach may be more beneficial. Striking the right balance ensures that quality is not compromised while still embracing modern efficiencies. It’s a journey that requires ongoing reflection and adjustment as technology evolves.

Manufacturing process automation brings remarkable flexibility to production lines. Companies can adjust workflows quickly to meet varying demands. When new products are introduced, automated systems can be reconfigured swiftly. This adaptability reduces downtime and helps maintain productivity levels. It also allows for a diverse range of products to be produced without major overhauls.

Scalability is another critical advantage. As the market shifts, businesses can scale operations up or down. Automation makes it easier to add or remove machinery as needed. However, this requires careful planning and ongoing evaluation. Missteps in scaling can lead to wasted resources or inefficiencies. Continuous monitoring is essential to ensure that automation meets the evolving needs of production. Embracing flexibility and scalability in automation could yield significant benefits, but it demands diligence and foresight.

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Efficiency | Automation speeds up production processes by reducing manual labor. | Higher output and lower labor costs. |

| Enhanced Quality Control | Automated systems provide consistent monitoring of production quality. | Reduction in defects and higher customer satisfaction. |

| Scalability | Easier to scale operations up or down based on demand. | Flexibility to meet market changes without significant downtime. |

| Cost Reduction | Less material waste and reduced operational costs. | Improved profit margins and sustainable operations. |

| Increased Productivity | Machines can operate continuously without breaks. | Higher throughput and faster time to market. |

| Improved Safety | Automation removes workers from hazardous environments. | Lower injury rates and insurance costs. |

| Better Data Collection | Automated systems gather and analyze performance data. | Data-driven decision making and process improvements. |

| Flexibility in Production | Ability to quickly switch production lines for different products. | Faster adaptation to market trends and customer preferences. |

| Sustainability | Reduced energy usage and waste management. | Lower environmental impact and improved public perception. |

| Customer Satisfaction | Faster response times and better product quality lead to happier customers. | Increased sales and repeat business. |

Manufacturing process automation offers numerous advantages for businesses, significantly transforming production practices. By implementing automation, companies can achieve enhanced efficiency, as automated systems streamline operations and reduce downtime. This leads to cost reduction and optimal resource utilization, allowing businesses to maximize output while minimizing expenses.

Moreover, manufacturing process automation ensures improved product quality and consistency, as machines perform tasks with precision, resulting in fewer errors. Increased flexibility and scalability in production enable companies to adapt quickly to market demands, while enhanced safety measures reduce workplace hazards, creating a healthier environment for employees. Overall, embracing manufacturing process automation can lead to sustainable growth and competitive advantage in today's dynamic market.