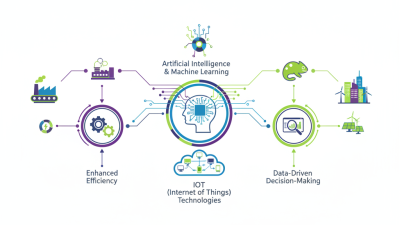

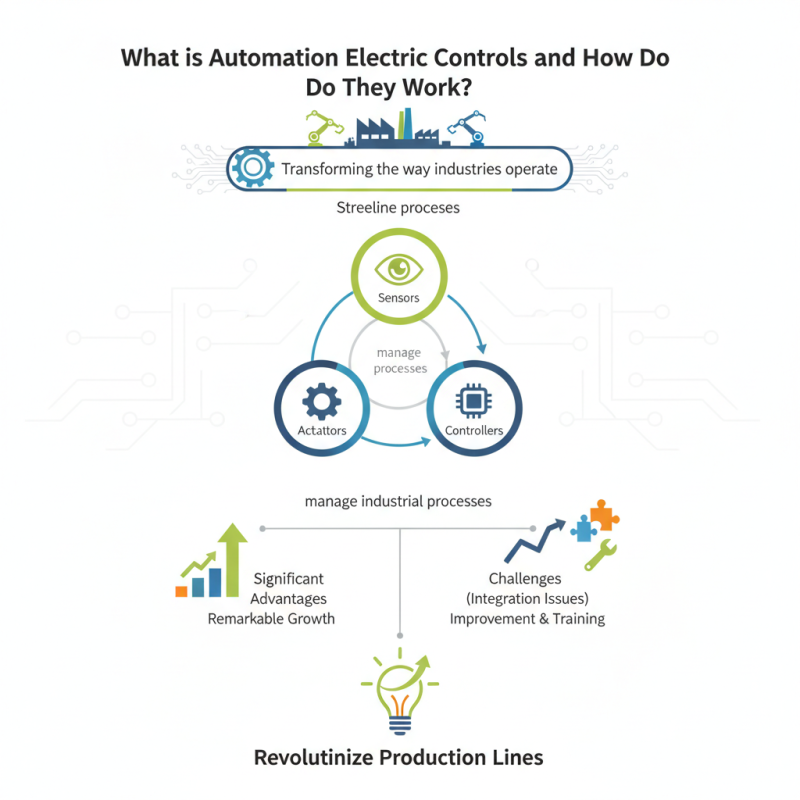

Automation electric controls are transforming the way industries operate. These systems streamline processes and enhance efficiency. According to Dr. Emily Chang, a leading expert in automation, “Effective automation electric controls can revolutionize production lines.” Her insights reflect the importance of these systems in modern manufacturing.

At the core of automation electric controls are sensors, actuators, and controllers. These components work together to manage industrial processes. Yet, not every implementation is flawless. Challenges like integration issues often arise. Organizations must be willing to adapt and learn from these hurdles.

Embracing automation electric controls offers significant advantages. However, businesses must also reconcile the realities of transition. It’s not simply a matter of installation. Continuous improvement and training are essential for success. Such efforts can lead to remarkable growth, making the journey worthwhile.

Automation electric controls play a crucial role in modern industrial processes. They allow machines and systems to operate automatically, reducing the need for human intervention. These systems can be as simple as a thermostat or as complex as an entire manufacturing line. The components typically include sensors, actuators, and a control unit. Sensors collect data from the environment. Actuators then respond by making adjustments based on the control unit's commands.

Understanding how these systems function can be complex. The interaction between the components is key. For example, sensors may detect temperature changes. They relay this information to the control unit. If the temperature is too high, the control unit activates the actuators to cool the system down. However, this process can be prone to errors. If a sensor malfunctions, the entire system may fail to respond correctly. This highlights the importance of regular maintenance and calibration.

Not all automation systems are perfect. Sometimes, they can be overly complicated or not user-friendly. Operators may struggle to decode error messages. This can lead to downtime and lost productivity. In this light, ongoing training for personnel becomes essential. Organizations often need to adapt to these challenges. Balancing efficiency with safety remains a constant struggle in implementing automation electric controls effectively.

This chart illustrates the distribution of different types of automation electric controls used in various industries. The data reflects the percentage of adoption for each control type, highlighting the popularity and application areas in automation technology.

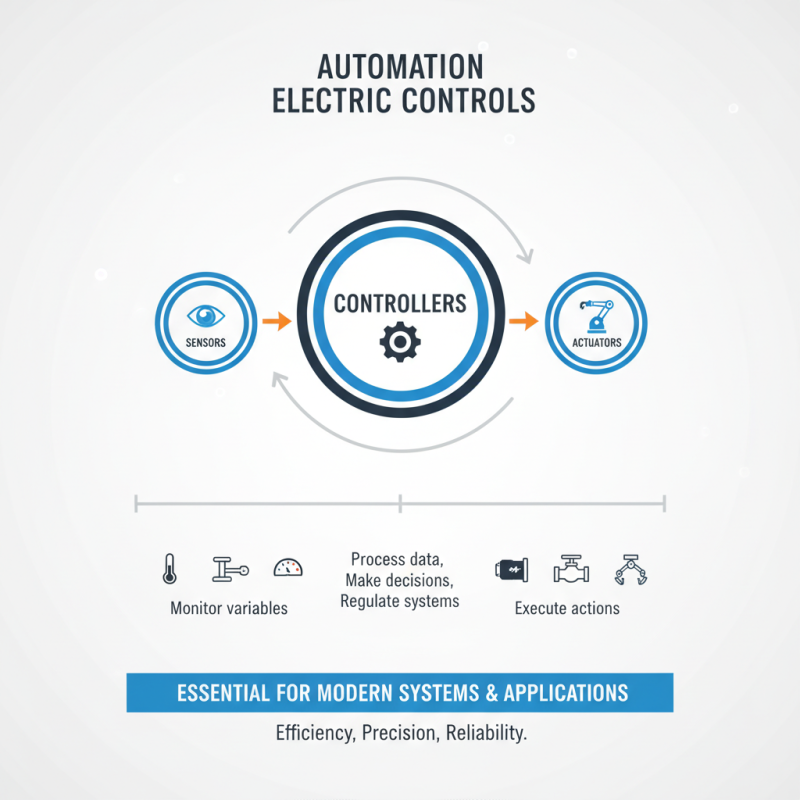

Automation electric controls are essential for many modern systems. They regulate and manage processes in various applications. Key components of these systems include sensors, controllers, and actuators.

Sensors play a crucial role. They gather data from the environment. For example, temperature sensors monitor heat levels. This information is vital for maintaining optimal conditions. However, sensors can sometimes fail. Accuracy is essential, and calibration is often needed.

Controllers process the data from sensors. They make decisions based on pre-set criteria. Programmable logic controllers (PLCs) are common in industrial settings. They can be complex and must be carefully programmed. Mistakes in programming can lead to unexpected results. It’s important to review and test these systems regularly. Actuators then carry out the commands given by the controllers. They can open valves or adjust motors. However, if an actuator is malfunctioning, it may not respond correctly. Regular maintenance helps minimize these issues.

In automation electric control systems, sensors play a critical role. They detect changes in the environment, such as temperature, pressure, and humidity. These changes are then converted into electrical signals. This process enables the control system to respond appropriately. Sensors ensure that machines operate efficiently. They provide real-time data that help in monitoring and adjustment.

Tips: Choose the right sensors for your application. Different sensors have unique capabilities. Make sure they suit your specific needs. Regularly check sensor calibration. An uncalibrated sensor can lead to errors and inefficiencies.

Another aspect to consider is sensor placement. Proper positioning can significantly affect performance. If a sensor is misplaced, it may not capture accurate data. This can create potential issues in the control system’s output. Understanding the environment and equipment is crucial for optimal sensor use.

Tips: Always test your sensors after installation. Simple tests can save you from larger problems later. Document sensor readings regularly. This practice can highlight trends and potential issues over time.

Automation electric controls play a crucial role in modern industrial settings. They regulate various processes, improving efficiency and safety. These systems often consist of sensors, controllers, and actuators. Sensors gather data from the environment. This data helps the system make decisions. The controller processes this information and sends commands to actuators.

The working principle is simple yet effective. For instance, in a manufacturing plant, sensors detect temperature changes. If the temperature exceeds a set threshold, the controller activates cooling systems. This prevents overheating. It’s a straightforward response to specific conditions. However, errors can occur. Incorrect sensor readings can lead to malfunctions. Regular maintenance is essential for reliable operation.

Moreover, not all situations are predictable. Human intervention may be needed at times. Engineers must analyze unexpected outcomes. Identifying patterns in failures is crucial for improvement. Automation systems are not foolproof. Each component must work as intended for the entire system to function properly. Continuous evaluation helps in refining these controls.

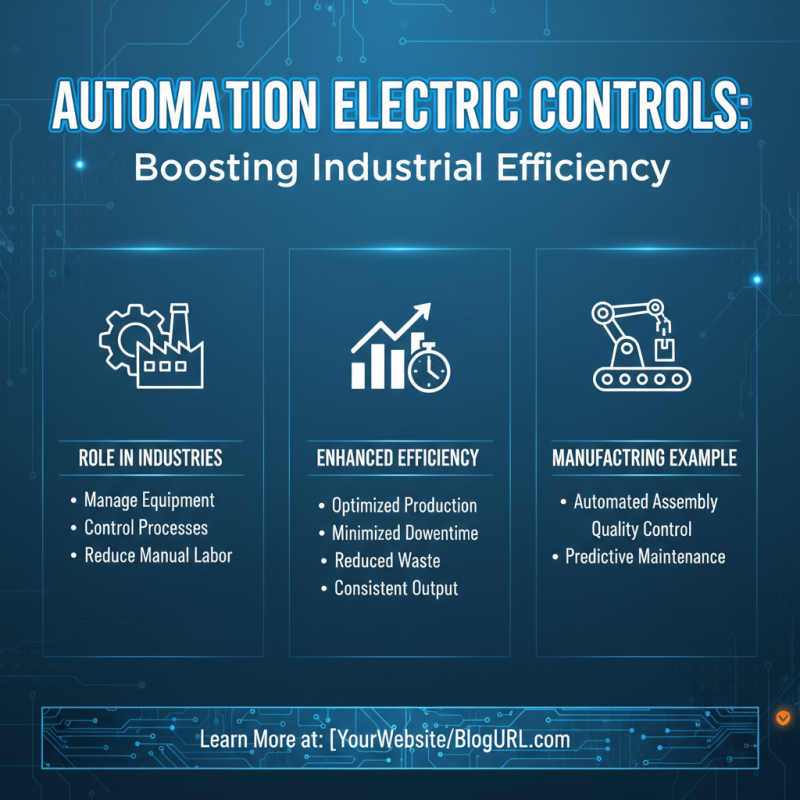

Automation electric controls play a crucial role in various industries. They enhance efficiency by managing equipment and processes without manual intervention. For instance, in manufacturing, these controls can optimize production lines. They ensure machines operate smoothly, reducing downtime and waste.

In the energy sector, automation controls help manage power generation and distribution. They monitor systems in real-time. However, implementing these systems can be challenging. Sometimes, improper setup leads to inefficiencies. Regular maintenance is critical to avoid unexpected failures.

Healthcare also benefits from automation electric controls. They help in monitoring patients and managing hospital equipment. Yet, reliance on these systems may raise concerns about data security. It’s essential to strike a balance between automation and human oversight for optimal outcomes.