In a rapidly evolving industrial landscape, the integration of automation electric controls is transforming operational paradigms, significantly enhancing efficiency and safety. According to a report by McKinsey, companies that adopt automation technologies can boost productivity by 20 to 25%, while reducing operational costs by as much as 30%. Furthermore, the International Federation of Robotics highlights that the use of advanced automation controls in manufacturing can decrease error rates and improve output quality, demonstrating their critical role in maintaining competitive advantage. As industries face increasing pressure to innovate and optimize processes, automation electric controls emerge as essential tools in driving sustainability and operational excellence.

By seamlessly integrating intelligent systems into industrial operations, businesses are not only enhancing their efficiency but also ensuring a safer working environment, making automation electric controls a focal point in the quest for modernization and growth.

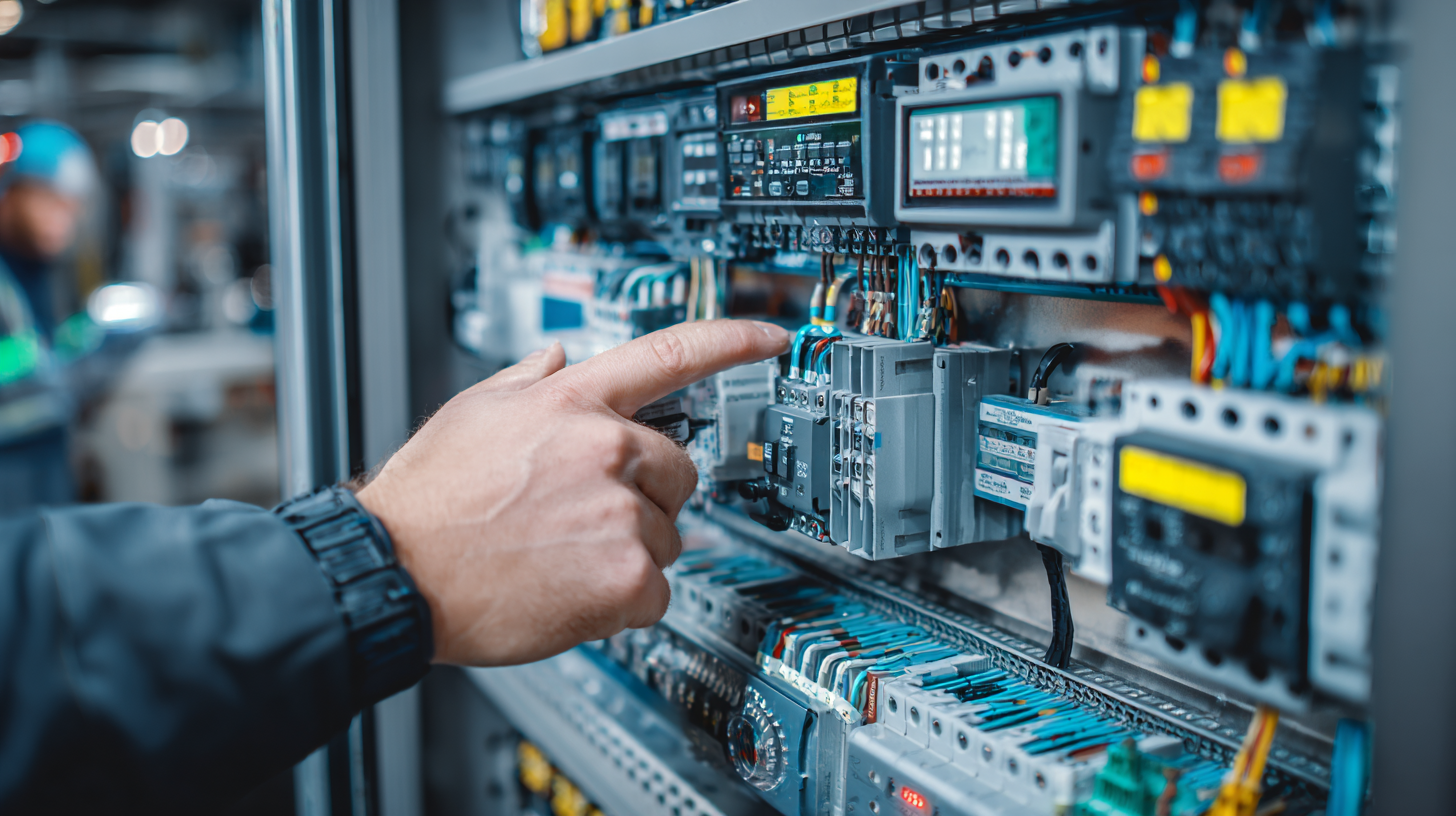

Automation electric controls play a critical role in modern industries by streamlining processes and enhancing operational efficiency. These control systems automate tasks that were once labor-intensive, allowing manufacturers to allocate resources more effectively and reduce human error. By integrating programmable logic controllers (PLCs) and advanced sensors, companies can monitor and manage equipment in real-time, leading to improved decision-making and increased safety standards.

**Tip:** Regularly updating your automation systems is essential to maintain optimal performance and compliance with industry regulations. Ensure that your team is trained on the latest technologies to fully leverage the benefits of automation.

The implementation of these controls not only boosts productivity but also significantly improves workplace safety. Automated systems can detect anomalies and respond rapidly to potential hazards, minimizing risks to personnel and equipment. Industries utilizing electric controls often report fewer accidents, as machines take on the dangerous tasks that would traditionally require human intervention.

**Tip:** Conduct routine safety audits of your automated systems to identify any potential vulnerabilities. Investing in preventative maintenance can save your organization from costly downtime and enhance overall safety measures.

| Industry | Efficiency Improvement (%) | Reduction in Human Error (%) | Safety Incidents Reduced (%) | Return on Investment (ROI) (%) |

|---|---|---|---|---|

| Manufacturing | 25 | 40 | 30 | 200 |

| Healthcare | 15 | 35 | 50 | 150 |

| Logistics | 20 | 30 | 40 | 180 |

| Energy | 30 | 20 | 25 | 220 |

| Agriculture | 18 | 25 | 15 | 190 |

In today's fast-paced industrial landscape, the implementation of automation electric controls is transforming how industries operate, significantly enhancing both efficiency and safety.

One of the primary benefits of automation in industrial settings is the boost in productivity. By leveraging advanced technologies such as robotics and AI-driven systems, industries can streamline operations, reduce human error, and increase output.

This results in faster turnaround times and allows companies to meet growing market demands without compromising on quality.

Moreover, automation enhances workplace safety by minimizing hazardous tasks performed by humans.

Automated systems can take on dangerous jobs, thereby reducing the risk of accidents and injuries.

Additionally, real-time monitoring and predictive maintenance features inherent in modern automation systems help identify potential issues before they escalate into serious problems, further safeguarding employees.

The combination of increased efficiency and improved safety not only contributes to a healthier work environment but also enhances the bottom line, making automation electric controls a crucial investment for forward-thinking industries.

Advanced control systems are significantly enhancing workplace safety through automation and real-time monitoring. As industries increasingly adopt smart technologies, the integration of automated electric controls allows for the proactive management of potential hazards. By leveraging data analytics and sensor technology, these systems can rapidly identify anomalies, reducing the likelihood of accidents and ensuring a safer work environment.

The global shift towards smart buildings is indicative of a larger trend in which automation plays a crucial role in efficiency and safety. The intelligent building market is expected to expand dramatically, reflecting a compound annual growth rate of 21.2% from 2025 to 2032. This growth underscores the importance of advanced control systems in maintaining optimal performance and safety standards. The commitment to enhancing workplace safety through innovative automation not only addresses current challenges but also prepares industries for future demands.

Integrating automation electric controls into existing operations is a critical step for industries aiming to enhance efficiency and safety. As companies grapple with the increasing complexity of manufacturing processes, the adoption of technologies like programmable logic controllers (PLCs) becomes essential. Recent developments in PLC technology, particularly concerning security vulnerabilities, emphasize the importance of not only implementing these systems but also safeguarding them against potential cyber threats. Organizations should begin by assessing their current systems and identifying areas where automation can lead to significant improvements.

Integrating automation electric controls into existing operations is a critical step for industries aiming to enhance efficiency and safety. As companies grapple with the increasing complexity of manufacturing processes, the adoption of technologies like programmable logic controllers (PLCs) becomes essential. Recent developments in PLC technology, particularly concerning security vulnerabilities, emphasize the importance of not only implementing these systems but also safeguarding them against potential cyber threats. Organizations should begin by assessing their current systems and identifying areas where automation can lead to significant improvements.

Next, it is crucial to develop a strategic plan for the integration process. This involves thorough training for engineers and operators on the new systems, ensuring they are well-equipped to manage and troubleshoot potential issues. Furthermore, industries like automotive manufacturing, where the integration of advanced multimedia systems is paramount, must prioritize collaboration between engineering teams and control system specialists. By fostering a culture of continuous improvement and technological adaptation, companies can optimize their workflows and enhance overall productivity while maintaining the highest safety standards.

As industries evolve, the next generation of automation technologies is set to transform how we approach efficiency and safety. One major trend is the integration of artificial intelligence and machine learning. These cutting-edge tools enable smarter decision-making processes and predictive maintenance, minimizing downtime and maximizing productivity. Companies embracing these innovations can expect not only streamlined operations but also enhanced worker safety as machines take on hazardous tasks.

**Tips:** Investing in AI-driven automation can be a game changer for operational efficiency. Start small by implementing these technologies in specific areas before scaling up. Additionally, ensure that all employees receive adequate training on new systems to help them adapt smoothly, fostering a culture of continuous improvement.

Another exciting trend is the deployment of advanced sensors and IoT devices. These technologies offer real-time data collection and analysis, allowing businesses to monitor their processes with unprecedented accuracy. With immediate access to critical information, organizations can react quickly to any anomalies, enhancing both safety and efficiency.

**Tips:** Consider utilizing a phased approach for IoT integration. Begin with a pilot project to evaluate the data insights received and gradually expand to ensure all systems work cohesively. This method not only reduces initial risks but also builds confidence in new technologies among team members.