In today's fast-paced manufacturing landscape, companies are increasingly turning to automated process control systems to enhance operational efficiency and maintain competitive advantage. According to a report by McKinsey & Company, the implementation of automation in manufacturing can boost productivity by up to 30%, illustrating the significant impact of these advanced technologies on industry performance. Moreover, a recent study from Deloitte highlights that organizations implementing automated control systems observe a marked decrease in operational costs, often reporting savings of 20-35%. These systems not only streamline workflows but also improve accuracy and consistency in production processes, leading to higher-quality outputs. As the global manufacturing sector continues to evolve, embracing automation is no longer a choice but a necessity for companies looking to thrive in a highly competitive environment.

The rise of automated process control in manufacturing has transformed the industry, enabling companies to enhance productivity and maintain consistency across production lines. With advancements in technology, manufacturers can implement sophisticated control systems that monitor and adjust processes in real-time. This shift towards automation reduces human error, streamlines operations, and allows for more precise control over variables such as temperature, pressure, and flow rates. As a result, companies are experiencing increased efficiency and reduced waste, driving down costs and improving overall quality.

Furthermore, the integration of automated process control systems paves the way for smarter manufacturing practices. With the advent of the Internet of Things (IoT) and data analytics, businesses can gather valuable insights from their operations. This data-driven approach facilitates predictive maintenance, enabling companies to address potential issues before they escalate into costly downtime. As manufacturers adapt to these automated solutions, they are not only maximizing their output but also fostering innovation and sustainability within their production environments. The rise of automated process control marks a significant leap forward in the quest for optimal manufacturing efficiency.

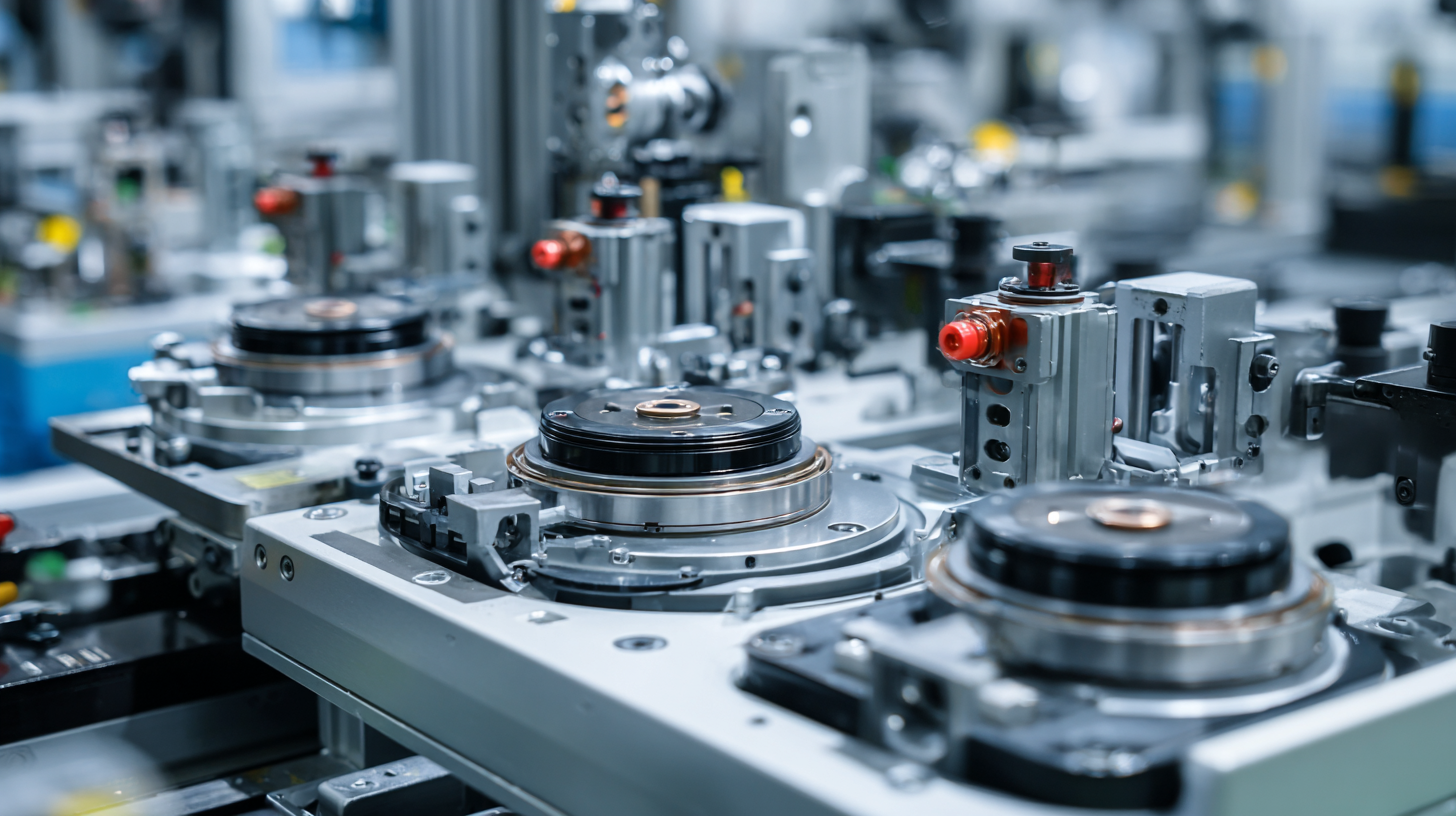

Automated process control systems are pivotal in transforming modern manufacturing into a more efficient and reliable operation. One of the key technologies driving this efficiency is the use of advanced sensors that facilitate real-time monitoring of production processes. These sensors collect data on various parameters such as temperature, pressure, and flow rates, enabling manufacturers to make informed decisions swiftly. By integrating this data into centralized control systems, businesses can optimize their workflows and respond to changes more rapidly, reducing downtime and improving overall productivity.

Another transformative technology is the implementation of machine learning algorithms in process control. By analyzing historical data, these algorithms can predict potential failures and maintenance needs before they occur, thus minimizing interruptions and enhancing the longevity of equipment. Additionally, the use of robotics in manufacturing processes has streamlined operations, allowing for precision and speed that human labor cannot match. Together, these technologies not only boost efficiency but also contribute to the sustainability of manufacturing practices by reducing waste and energy consumption, ensuring that modern manufacturing meets both economic and environmental goals.

In the rapidly evolving landscape of modern manufacturing, real-time data analytics has emerged as a critical backbone for enhancing operational efficiency. According to a report by McKinsey, companies leveraging advanced data analytics can see improvements of up to 20% in productivity and a significant reduction in downtime. This shift towards data-driven decision-making allows manufacturers to monitor processes in real time, identifying potential bottlenecks before they escalate into costly issues.

The integration of automated process control systems further complements this analytics-driven approach. A study by Deloitte highlights that organizations employing automation and real-time data insights can reduce operational costs by as much as 15%. By capturing and analyzing data as it flows through production lines, manufacturers can optimize workflows, reduce waste, and ensure quality consistency. This synergy not only empowers businesses to respond swiftly to market changes but also fosters a culture of continuous improvement, essential for maintaining a competitive edge in today’s manufacturing landscape.

Automated process control systems are transforming modern manufacturing by enhancing efficiency and precision. In an automotive manufacturing case study, a major car manufacturer implemented an automated assembly line that integrated robotics and real-time monitoring. This system reduced production time by 20% and significantly minimized errors in the assembly process. The automation not only streamlined operations but also allowed for greater flexibility in adapting to changing production demands.

Another notable example comes from the food processing industry, where a leading company adopted an automated system for ingredient mixing and packaging. This system utilized sensors and predictive analytics to ensure optimal ingredient ratios and timely packaging. As a result, the company saw a remarkable 30% reduction in waste and a 15% increase in overall productivity. These case studies illustrate how automated process control systems not only double efficiency but also pave the way for innovation and sustainability in manufacturing processes.

As we look to the future, the landscape of manufacturing automation is set for a

remarkable transformation. Advanced technologies such as

artificial intelligence, machine learning, and the Internet of Things (IoT) are poised to

redefine operational efficiencies. These innovations will enable

real-time data analytics, allowing manufacturers to make informed decisions

instantly, thus enhancing production workflows. The integration of smart devices and sensors

will facilitate a more interconnected production environment, where machines communicate

seamlessly, optimize processes, and predict maintenance needs before costly breakdowns occur.

Moreover, the advent of flexible automation systems is

revolutionizing how manufacturers respond to market demands. Companies are increasingly

adopting modular equipment that can be reconfigured for different tasks without significant

downtime. This adaptability not only streamlines operations but also supports the

customization of products at scale. As these trends develop, we will likely see a surge in

collaborative robots, or cobots, working alongside human operators, enhancing

safety while improving productivity. The future of manufacturing automation promises not only

to boost efficiency but also to

empower workers, fostering an agile environment

capable of thriving in an ever-changing industrial landscape.