In the realm of industrial automation, the pursuit of efficiency is paramount. One of the most effective strategies for achieving this goal lies in the implementation of advanced process control (APC) systems. These sophisticated methodologies enable organizations to optimize their operations by employing real-time data and predictive algorithms, thus improving overall process reliability and reducing waste. As industries face increasing competition and the pressure to lower operational costs, understanding and leveraging APC becomes a critical component of modern industrial practices.

Advanced process control not only enhances process accuracy and consistency but also offers the ability to adapt to varying operational conditions, ensuring that systems operate at peak performance. By incorporating advanced algorithms and machine learning techniques, industries can respond dynamically to fluctuations, thereby maximizing productivity and minimizing downtime. This introduction to APC principles emphasizes the importance of integrating technology within industrial frameworks as a means of driving continuous improvement.

As we delve into the essential tips for optimizing industrial automation efficiency through advanced process control, it becomes evident that investing in these innovative strategies is not merely beneficial but essential for organizations aiming to thrive in an ever-evolving market landscape. Embracing APC principles equips businesses with the tools necessary to meet current challenges while paving the way for future advancements, ultimately leading to sustainable growth and enhanced operational effectiveness.

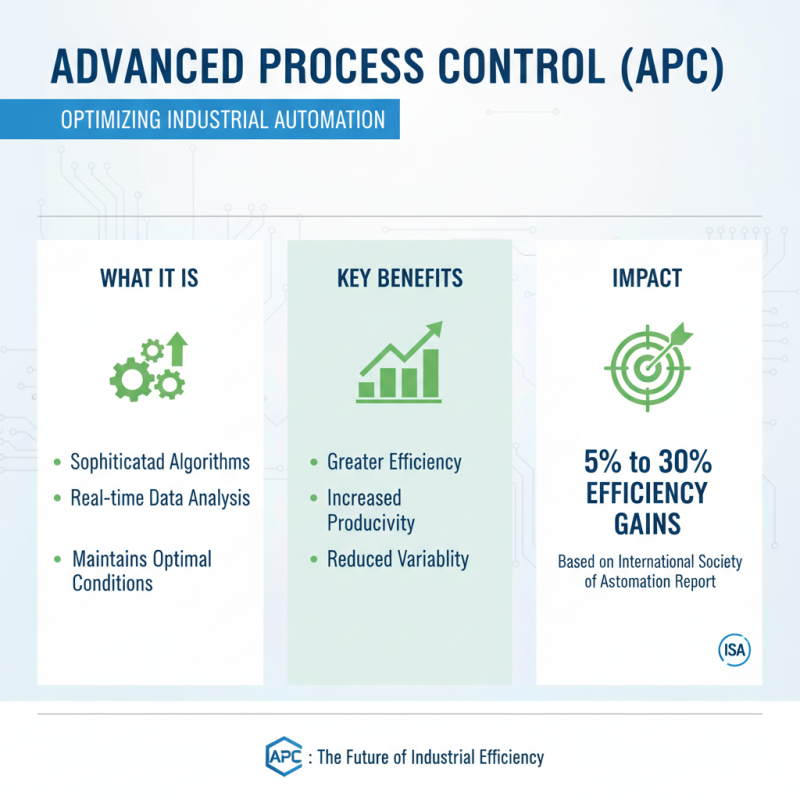

Advanced Process Control (APC) plays a pivotal role in enhancing industrial automation by optimizing processes to achieve greater efficiency and productivity. By leveraging sophisticated algorithms and real-time data analysis, APC systems enable manufacturers to maintain optimal operating conditions, minimize variability, and increase throughput. According to a recent report by the International Society of Automation, companies implementing APC have observed efficiency gains ranging from 5% to 30%, depending on the industry and specific applications.

Moreover, the integration of APC with emerging technologies such as machine learning and the Internet of Things (IoT) allows for continuous improvement and predictive maintenance. As per a study by MarketsandMarkets, the global market for advanced process control was valued at approximately $2.76 billion in 2020 and is projected to reach $5.14 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.9%. This growth underscores the increasing recognition of APC's value in driving operational excellence and cost savings.

In practical terms, the implementation of APC can lead to reduced energy consumption, improved product quality, and enhanced safety measures within industrial facilities. By focusing on advanced control strategies, industries can not only respond to immediate operational challenges but also position themselves competitively in a rapidly evolving market landscape. The effective application of these techniques is essential for organizations aiming to fully harness the benefits of automation in their processes.

Enhancing process efficiency and stability in industrial automation is crucial for maintaining competitive advantage and operational excellence. One key technique involves the implementation of predictive maintenance strategies. By utilizing advanced analytics and sensor data, industries can foresee potential equipment failures before they result in costly downtimes. This foresight not only improves the reliability of machinery but also allows for more informed scheduling of maintenance activities, ultimately reducing waste and increasing overall productivity.

Another important aspect is the optimization of control algorithms. Utilizing model-based control approaches, such as advanced PID tuning or state-space methods, can significantly improve system responses and stability. These sophisticated algorithms can adapt to changing process dynamics, ensuring that the desired outputs are consistently met even under varying conditions. Furthermore, integrating real-time data into control strategies enhances decision-making processes, enabling quicker responses to fluctuations in operational parameters. By focusing on these advanced techniques, industries can achieve substantial improvements in both efficiency and stability in their automation processes.

This bar chart illustrates the efficiency percentages of different industrial processes. Optimizing these processes can lead to significant improvements in overall automation efficiency and stability.

Model Predictive Control (MPC) has emerged as a leading strategy in advanced process control, enabling industrial automation systems to achieve optimal performance through predictive capabilities. At its core, MPC utilizes mathematical models to forecast future behavior of processes, allowing operators to anticipate changes and make informed, real-time decisions. By continuously evaluating performance and adjusting control actions accordingly, MPC dramatically enhances efficiency and reduces waste in industrial operations.

Implementing MPC involves several key steps, including model development, performance assessment, and ongoing refinement. Accurate modeling of the processes is vital, as it relies on both physical insights and data. With a robust model in place, operators can simulate various scenarios to identify optimal control strategies. Furthermore, MPC's ability to accommodate multi-variable dynamics and constraints ensures that systems operate within defined parameters while maximizing throughput. The flexibility of MPC also allows for easy adaptation to changing operating conditions, making it particularly valuable for complex industrial environments. As organizations continue to seek ways to optimize their operations, the implementation of MPC stands out as a formidable approach to achieving greater efficiency and performance.

In today's fast-paced industrial landscape, the application of data analytics has emerged as a vital instrument for enhancing process efficiencies across various sectors. A recent report by McKinsey indicates that companies leveraging advanced analytics can improve their operational performance by up to 15%. By employing sophisticated algorithms and machine learning techniques, organizations can gain deep insights into their processes, identifying inefficiencies that might otherwise go unnoticed.

Data analytics enables manufacturers to optimize production schedules, reduce downtime, and enhance resource allocation. According to a study from the International Society of Automation, companies utilizing predictive analytics have seen a reduction in maintenance costs by as much as 30% due to proactive identification of potential equipment failures. This proactive approach not only minimizes disruptions but also allows for a seamless flow of operations, further driving efficiency. As industries continue to embrace these data-driven methodologies, the potential for continual improvement becomes increasingly tangible, positioning businesses to adapt in an ever-evolving market.

| Tip Category | Description | Data Analytics Utilization | Expected Improvement (%) |

|---|---|---|---|

| Predictive Maintenance | Use data analytics to predict equipment failures and schedule maintenance. | Machine learning algorithms analyze historical data. | 20% |

| Process Optimization | Implement algorithms that continuously adjust process parameters. | Real-time data monitoring and feedback systems. | 15% |

| Energy Management | Analyze energy usage patterns to identify savings opportunities. | Statistical analysis of energy consumption data. | 25% |

| Quality Control | Integrate analytics into inspection processes to reduce defects. | Use of control charts to monitor quality metrics. | 30% |

| Supply Chain Analytics | Optimize inventory and logistics based on predictive models. | Predictive analytics on demand forecasting. | 18% |

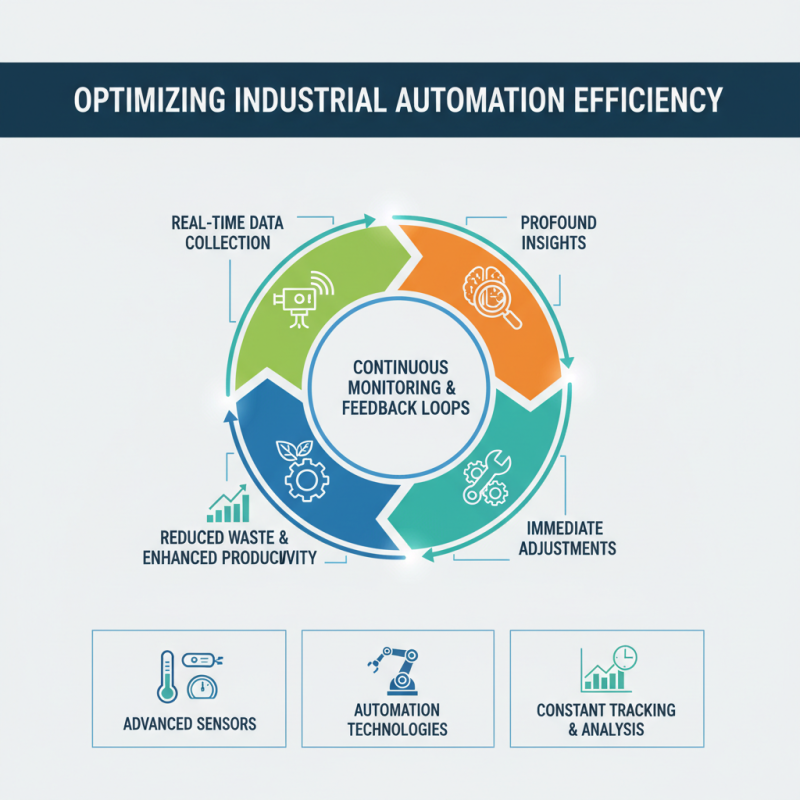

Continuous monitoring and feedback loops are essential components in optimizing industrial automation efficiency. By utilizing real-time data collection, industries can gain profound insights into their operational processes. This constant stream of information allows for immediate adjustments to be made, reducing waste and enhancing productivity. Advanced sensors and automation technologies facilitate this process, ensuring that parameters such as temperature, pressure, and flow rates are constantly tracked and analyzed.

Implementing feedback loops in automation systems enables a proactive approach to process control. When deviations from desired performance metrics occur, automated corrective actions can be triggered without human intervention, ensuring that processes remain stable and efficient. Moreover, these feedback mechanisms can be refined and improved over time, learning from past data trends and operator inputs to enhance decision-making. By integrating continuous monitoring with effective feedback loops, organizations can not only maintain optimal conditions but also innovate their procedures, ultimately driving long-term operational success.