In recent years, manufacturing process automation has become a pivotal focus for industries worldwide. According to a report by McKinsey, nearly 60% of manufacturing tasks could be automated using current technologies. This shift emphasizes the need for advanced automation solutions. Companies aim to enhance productivity, minimize costs, and improve quality. The global market for automation technologies is projected to grow by 9% annually, reaching over $300 billion by 2026.

As manufacturers adopt these technologies, challenges also arise. Integration of new systems with existing processes can be complex. Many companies struggle with workforce training and reskilling, which are crucial for optimal automation. Moreover, a survey by PwC found that only 50% of executives believe their teams are prepared for this transition. These gaps highlight the necessity of a strategic approach to manufacturing process automation.

In the quest for efficiency, manufacturers must remain vigilant. Continuous assessment of automation technologies and their impact is essential. Embracing change calls for a critical evaluation of both successes and pitfalls. The journey toward automation is not just about implementation; it requires an ongoing commitment to improvement and adaptation. As trends evolve, so too must the strategies that govern manufacturing process automation.

The landscape of manufacturing process automation is set to evolve considerably by 2026. Key technologies driving this change include artificial intelligence (AI), the Internet of Things (IoT), and advanced robotics. According to a recent industry report, 85% of manufacturers plan to integrate AI into their operations by 2026. This shift can enhance efficiency, but it also raises questions about workforce displacement.

IoT devices will become more ubiquitous, facilitating real-time data collection. Reports indicate that by 2025, the number of connected IoT devices in the manufacturing sector could exceed 75 billion. This connectivity will provide manufacturers with valuable insights, but it also presents cybersecurity challenges. Companies must invest in robust security measures to protect their data while embracing these technologies.

Advanced robotics will further reshape manufacturing environments. Experts predict that by 2026, around 70% of production tasks will be automated. However, the reliance on robots may lead to a lack of adaptability in production lines. Balancing automation with human skills will be crucial as the industry navigates these changes. The journey towards automation is filled with opportunities, yet reflections on workforce impacts and security vulnerabilities should not be overlooked.

As we dive into the realm of robotics and AI, the future of manufacturing is transforming rapidly. Robotics is becoming more accessible and user-friendly. Many factories are adopting collaborative robots, or cobots, that work alongside human workers. These robots perform repetitive tasks, allowing humans to focus on more complex problems. The synergy between humans and machines is crucial for improved productivity and safety.

AI advancements are also revolutionizing automation processes. Intelligent algorithms analyze vast amounts of data in real-time. This capability enhances decision-making and operational efficiency. However, implementing AI isn't without challenges. Companies often struggle with data integration issues and the potential for job displacement. Finding the right balance between innovation and workforce impact is essential for sustainable growth.

Moreover, the speed of adoption poses risks. Many businesses rush into automation without proper planning. This haste can lead to costly mistakes and inefficiencies. Additionally, the reliance on technology raises concerns about cybersecurity. As systems become increasingly interconnected, they may become targets for cyber threats. The future is bright, but it demands careful consideration and strategic implementation.

| Trend | Description | Technology | Impact | Adoption Rate (%) |

|---|---|---|---|---|

| Advanced Robotics | Use of collaborative robots working alongside humans. | Collaborative Robots (Cobots) | Increased productivity and safety. | 65 |

| Artificial Intelligence | AI algorithms for predictive maintenance. | Machine Learning, Predictive Analytics | Reduced downtime and operational costs. | 70 |

| Internet of Things (IoT) | Connected devices for real-time monitoring. | IoT Sensors, Smart Equipment | Enhanced decision making and efficiency. | 75 |

| Digital Twin Technology | Virtual replicas of physical systems for analysis. | Simulation Software, 3D Modeling | Optimization of production processes. | 60 |

| Edge Computing | Processing data near the source to enhance speed. | Edge Devices, Distributed Cloud | Reduced latency in data processing. | 55 |

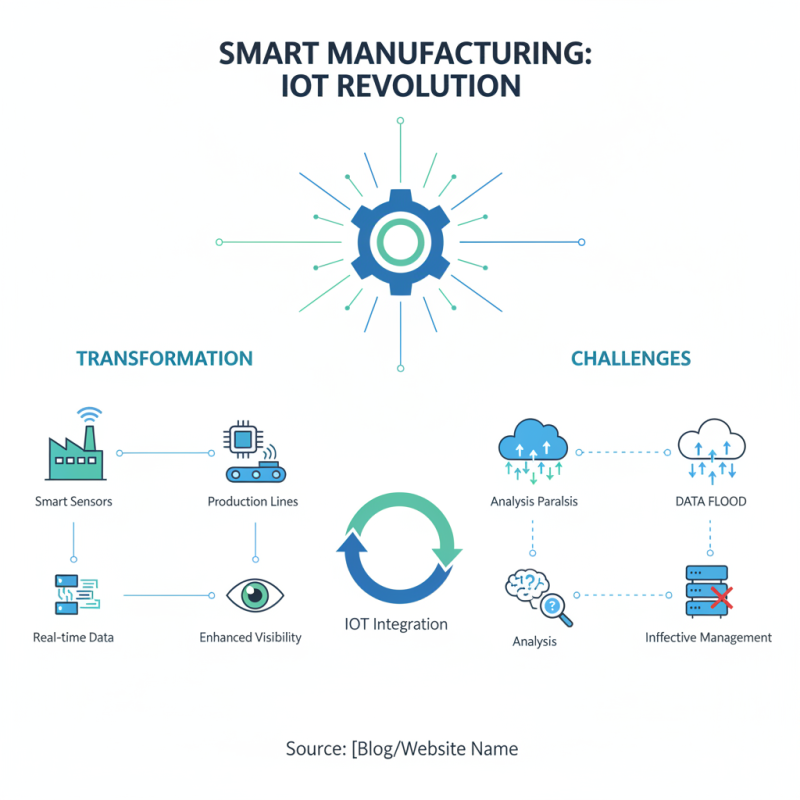

The integration of the Internet of Things (IoT) in manufacturing is transforming operations. Smart sensors are being deployed across production lines. These devices collect real-time data, enhancing visibility into processes. However, challenges arise in managing this data effectively. Companies often struggle to analyze the influx of information generated.

Data management systems must evolve alongside IoT technology. Many manufacturers find their existing systems inadequate for handling large volumes of data. This can lead to misinterpretations or missed opportunities for improvement. It is essential to invest in robust analytics tools that can simplify this process. Still, many organizations hesitate due to the costs involved.

Streamlining manufacturing processes through IoT requires careful planning. Companies should prioritize specific areas, assessing where automation can yield the best outcomes. Yet, the temptation to automate everything can lead to complications. Automation is not a cure-all; it requires thoughtful implementation. Hence, a balance between technology and human oversight is crucial for success.

Sustainable practices are transforming the landscape of manufacturing automation. Reports indicate that 70% of manufacturers are investing in green technologies. Innovations like energy-efficient robots and smart sensors play a key role. These advancements not only reduce waste but also cut energy consumption.

A recent study found that manufacturing can reduce costs by up to 30% when implementing sustainable automation. This often leads to shorter production cycles and less waste. However, many companies struggle with the initial investment. Transitioning to these technologies requires careful planning and training.

Tip: Start small. Pilot projects can help assess the viability of sustainable automation.

Additionally, collaboration among teams is essential. Different departments should share insights. This can identify areas for improvement. Regular assessments of automation processes are crucial. They ensure that these sustainable practices are effective and evolve with new technologies.

Tip: Set measurable goals. Assess their impact on sustainability and efficiency.

Manufacturers must remain adaptable as innovations arise. Embracing change is vital, yet it can be daunting. Each step toward sustainability is a learning experience. The journey to efficient automation is ongoing.

In recent years, the role of advanced analytics in manufacturing automation has grown significantly. Manufacturers now leverage big data to drive decisions. This process is far from simple. Many firms struggle to integrate analytics into their existing systems. They face challenges with data quality and consistency. Without reliable data, insights become questionable.

Advanced analytics can optimize operations. Predictive maintenance, for example, minimizes downtime. By analyzing patterns, manufacturers can forecast equipment failures. However, many still rely on outdated methods. Some decision-makers resist change. They may prefer traditional approaches over new technology. This reluctance can hinder progress.

The true potential of advanced analytics lies in its ability to provide actionable insights. Real-time data can lead to quicker decisions. Yet, not all manufacturers have access to real-time analytics. Disparities in technology adoption are evident. Moreover, understanding the data requires skilled personnel, which can be a challenge for some organizations. Investing in training and technology is crucial for success.