The automation machinery manufacturing industry stands at a crucial crossroad. As we approach 2026, emerging trends are reshaping this landscape. A recent report from the International Federation of Robotics noted a projected growth rate of 10% in industrial automation in the next five years. This surge reflects significant innovations and market demands.

Experts like Dr. Emily Carter, a leading authority in automation processes, highlight the importance of adaptability. "The future of automation machinery manufacturing lies in our ability to innovate continuously," she stated in her recent interview. This sentiment aligns with the shift toward smart factories and AI integration. However, challenges remain. Companies struggle with integrating new technologies and workforce training.

Investments in automation are rising, yet companies face skills gaps. The need for technical knowledge is vital, yet many firms are ill-prepared. As businesses navigate these trends, reflection on both successes and shortcomings becomes essential. Embracing these changes in automation machinery manufacturing could define the industry's future.

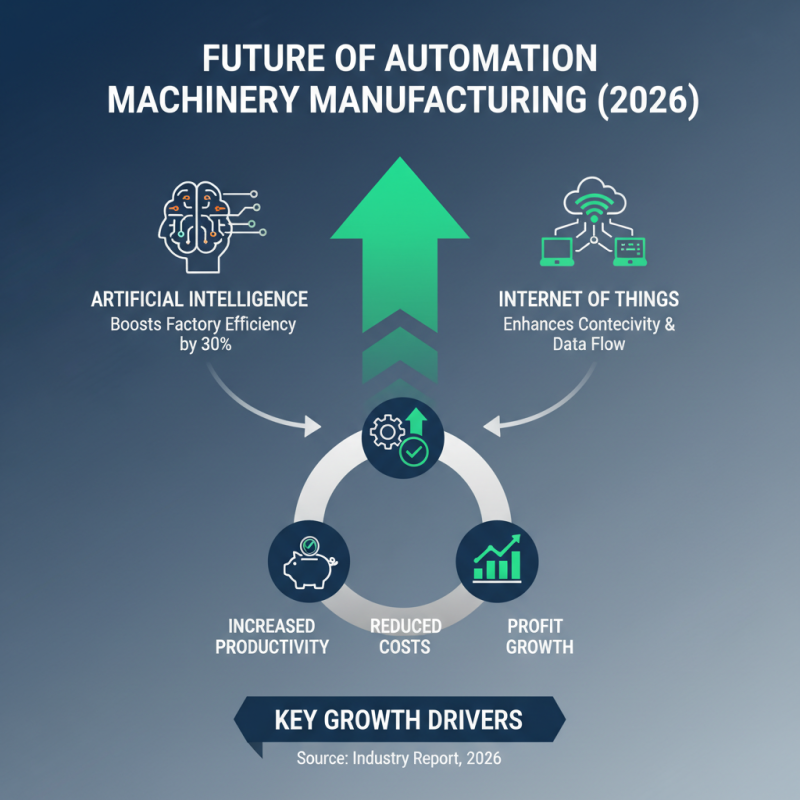

The landscape of automation machinery manufacturing is rapidly changing. In 2026, key drivers of growth will include advancements in artificial intelligence and the Internet of Things (IoT). According to a recent industry report, AI can improve factory efficiency by up to 30%. This efficiency translates directly into reduced costs and higher productivity.

With automation becoming more accessible, small and medium-sized enterprises will increasingly adopt these technologies. Knowledge gaps, however, persist. Training and upskilling workers is crucial. Companies that invest in human capital will see better outcomes.

Tips: Focus on integrating IoT sensors in production lines. These devices provide real-time data, aiding quick decision-making. Another tip is to recognize the limitations of automation. Not every task can or should be automated. Human insight remains vital in complex problem-solving. Craftsman skills and creativity are irreplaceable.

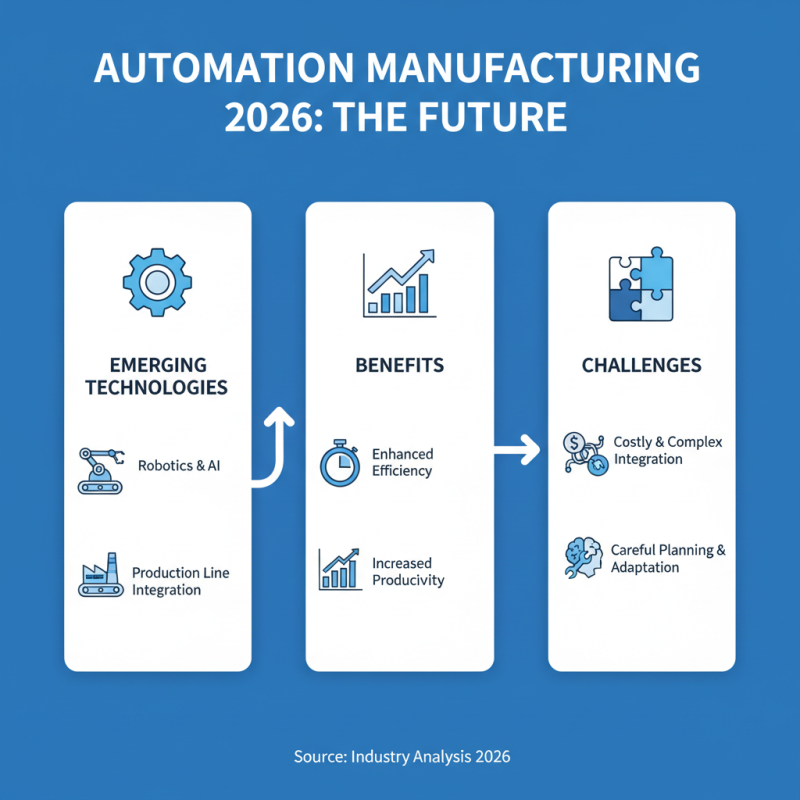

As we look towards 2026, automation machinery manufacturing is poised for significant transformation. Emerging technologies are reshaping how factories operate. Robotics and artificial intelligence are becoming integral parts of production lines. These innovations promise to enhance efficiency and productivity. However, implementing such systems also presents challenges. Integration can be costly and complex, demanding careful planning and adaptation from businesses.

Additionally, the rise of the Internet of Things (IoT) brings new opportunities and concerns. Smart devices can provide real-time data, improving decision-making. Yet, this connectivity raises cybersecurity issues. Protecting sensitive information is crucial in an increasingly digital world. Companies must strike a balance between innovation and security.

Sustainability is also key in this evolving landscape. Automation can reduce waste and energy consumption but requires investment in eco-friendly technologies. Many manufacturers are exploring renewable energy sources to power operations. Adopting green practices is essential, although it can require a cultural shift within organizations. Embracing these changes is imperative for the future of automation machinery manufacturing.

The rise of artificial intelligence (AI) is transforming the landscape of automation systems.

AI enhances precision in manufacturing processes. It reduces human error and improves efficiency. Intelligent machines can analyze vast amounts of data, making real-time decisions. This capability speeds up production and optimizes resource usage. However, the integration of AI is not without challenges.

Many companies face implementation hurdles. Identifying the right AI technologies is complex. Training staff to work with these systems demands time and investment. Some organizations struggle with data management, as quality is crucial for AI success. Not all data is structured or clean. This can lead to inaccuracies in AI outputs. Therefore, a balance between automation and human oversight remains essential.

AI also brings ethical considerations. Decision-making by machines prompts questions about accountability. If a machine makes a mistake, who is responsible? This uncertainty can hinder adoption. Organizations must reflect on these concerns while embracing AI. The journey towards full automation will require careful navigation of these issues.

The shift towards sustainability in automation machinery production is notable. Reports indicate that around 60% of manufacturers are striving to reduce their carbon footprint. This trend aligns well with global efforts to combat climate change. Many companies are implementing energy-efficient practices. This shift not only aids the planet but also enhances operational efficiency.

Material selection is another crucial factor. Sustainable raw materials, such as recycled metals and biodegradable plastics, are gaining traction. The use of these materials can lower waste significantly. Research shows that using recycled materials can reduce energy consumption by up to 75%. However, the initial cost may deter some manufacturers. Balancing cost and sustainability is a challenge still being navigated.

Moreover, technology plays a vital role in achieving sustainability. Automation companies increasingly rely on smart systems to monitor energy usage. These systems can pinpoint inefficiencies and suggest improvements. Yet, not all companies are adapting quickly. Some still cling to outdated practices that don’t align with new sustainability standards. The journey may require reflection and a commitment to change.

The global supply chain landscape is evolving rapidly in automation machinery manufacturing. Innovations are driving efficiency, reducing costs, and enhancing productivity. According to a recent report by the International Federation of Robotics, automation adoption can boost productivity by 30% in manufacturing sectors. This shift indicates a move toward smarter factories and interconnected processes.

Sourcing strategies are being redefined. Many companies are investing in AI and machine learning to analyze data more effectively. For instance, predictive analytics can help forecast demand and optimize inventory levels. However, challenges remain. Supply chain disruptions from recent global events highlighted vulnerabilities. Companies face pressure to be agile and adaptable. Building resilience in supply chains is now crucial.

Collaboration among suppliers is becoming vital. The trend towards localized production is gaining traction. This minimizes transportation costs and reduces lead times. Data from industry experts suggest that companies embracing local sourcing see a 25% decrease in delays. While innovation is promising, it requires thoughtful implementation. Balancing technology with human skills remains a concern; workforce adaptation is not keeping pace with changes in automation.

This chart depicts the projected growth percentages of key trends in automation machinery manufacturing as part of global supply chain innovations.